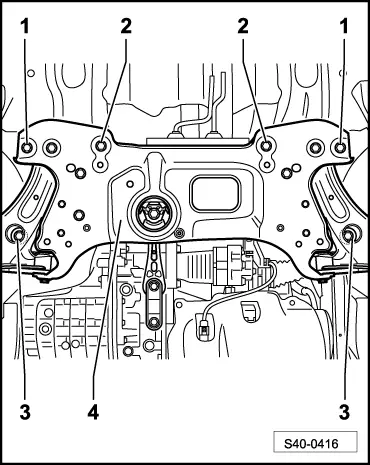

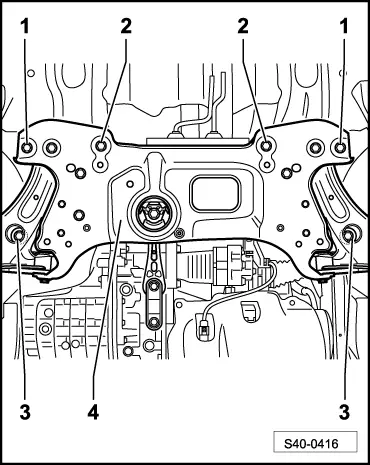

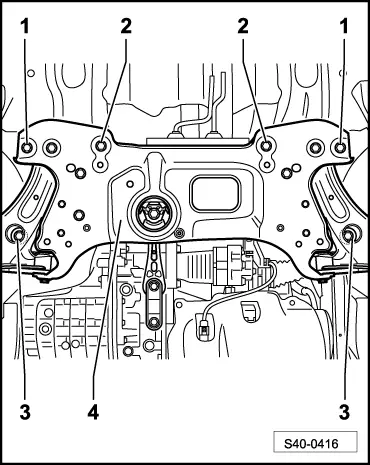

| Fixing devices -T10452- (larger diameter) in positions -3- |

Note | The fixing devices -T10096- and - T10452- must only be tightened to maximum 20 Nm as otherwise the threads of the fixing bolts can be damaged. |

| –

| Successively screw out the fixing screws of the assembly carrier/body -2- and replace on both sides with the fixing devices -T10096- (smaller diameter) and tighten to 20 Nm. |

| –

| Support assembly carrier with engine/gearbox jack, e.g. -V.A.G 1383/A-. |

| –

| Successively screw out the fixing screws of the assembly carrier/body -3- and replace on both sides with the fixing devices -T10452- (larger diameter) and tighten to 20 Nm. |

| The position of the front axle is now fixed. |

| If it is not possible to insert the fixing devices -T10096- or -T10452- into the corresponding openings of the assembly carrier, the following measures must be carried out: |

| –

| Prepare the inlet openings in the lower area of the assembly carrier e.g. with a file so that the fixing devices -T10096- or -T10452- can be inserted into the openings. |

| –

| Treat the prepared openings against corrosion e.g. with zinc spray -D 007 500 04-. |

| Installation is carried out in the reverse order. |

| –

| Successively replace the fixing devices -T10096- and - T10452- with new screws. |

| –

| Tighten screws to corresponding tightening torque → Anchor. |

Note | It is necessary to perform a vehicle alignment in the event of: → Chapter |

| –

| Check the steering wheel position during the test drive. |

Note | If after the test drive and with the wheels pointing straight ahead the steering wheel is off straight, perform a chassis alignment → Chapter. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note