| –

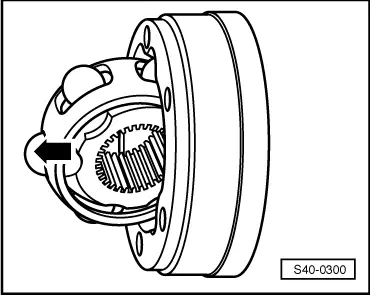

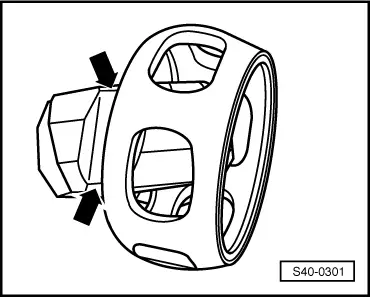

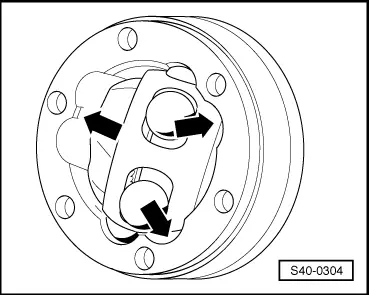

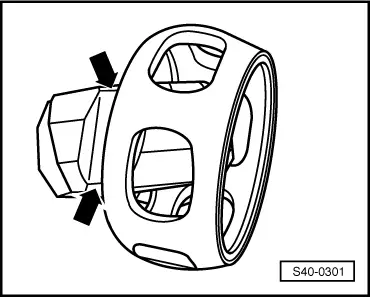

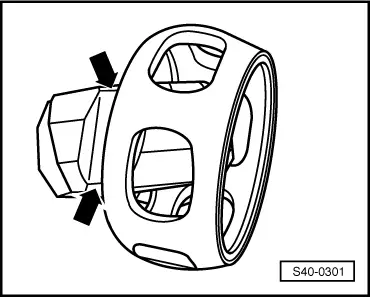

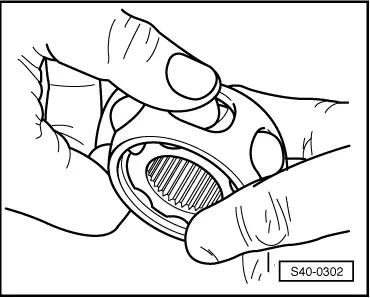

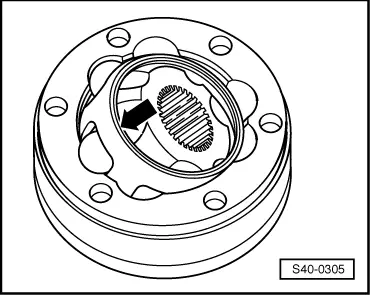

| Tilt the ball hub out of the ball cage over the ball bearing track -arrows-. |

| –

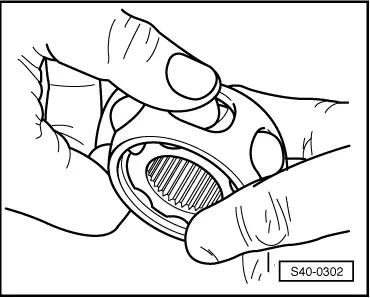

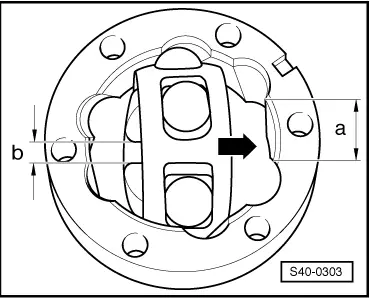

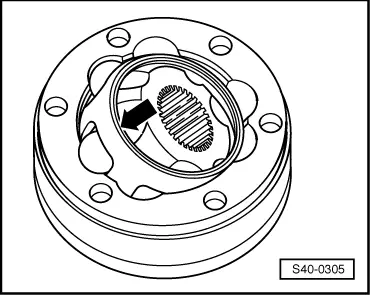

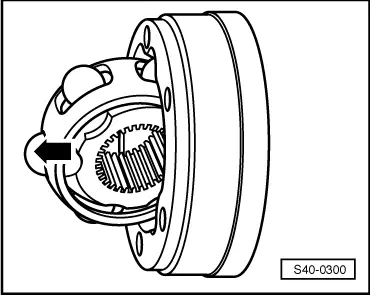

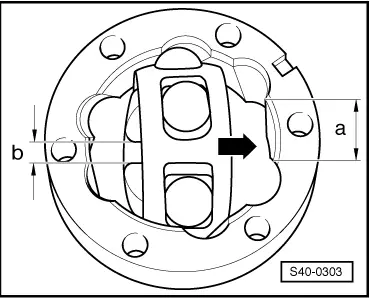

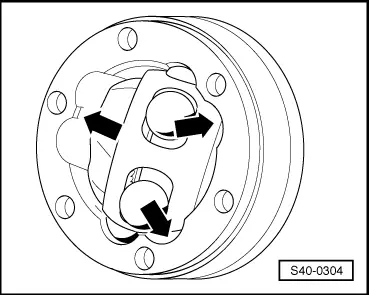

| Inspect the joint part, ball hub, ball cage and balls for small broken out depressions (pitting = point corrosion) and seizing marks. |

| Load alteration shocks indicate too much torsional clearance in the joint. If this is the case, replace the joint. Smoothing and bearing marks do not justify a joint replacement. |

|

|

|

Note

Note

Note

Note