Drive shaft to wheel hub with wheel bearing „hexagon screw“| t

| Vehicle must not be standing on its wheels for tightening the screw |

| 200 Nm + 180° |

Drive shaft to wheel hub with wheel bearing „twelve-sided bolt“| t

| Vehicle must not be standing on its wheels for tightening the screw |

| 70 Nm + 90° |

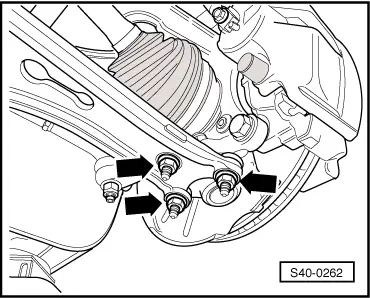

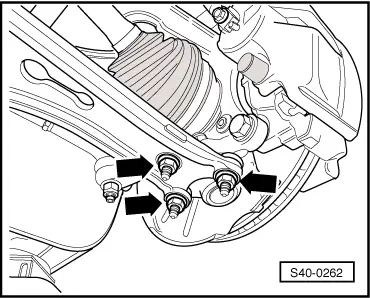

| Drive shaft to gearbox mounting flange | Tighten crosswise! |

| t

| First of all pre-tighten to 10 Nm crossways |

| M8 = 40 Nm

M10 = 70 Nm |

| Steering joint to track control arm | |

| t

| Track control arm made of steel casting |

| 60 Nm |

| t

| Track control arm made of steel sheet |

| 100 Nm |

| Drive shaft screening | 25 Nm |

| Wheel bolts | 120 Nm |

Note

Note

Note

Note Note

Note Note

Note