| l

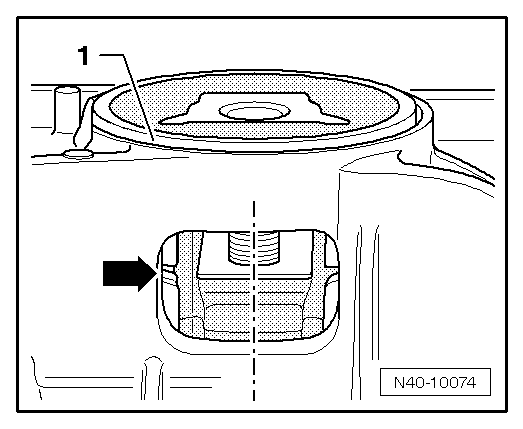

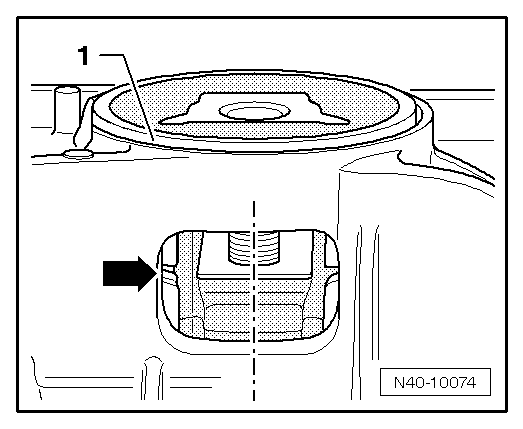

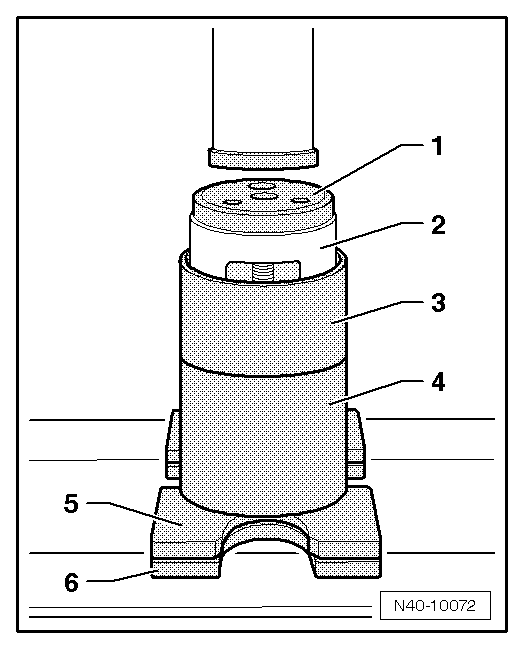

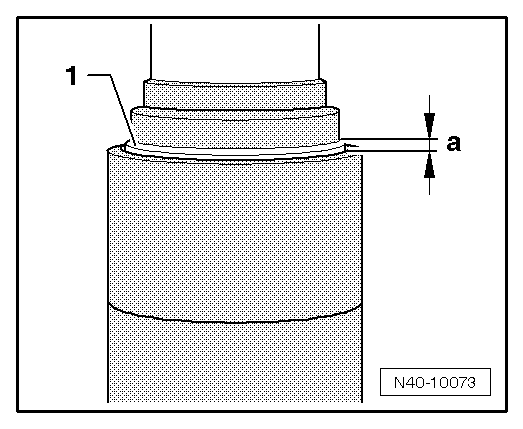

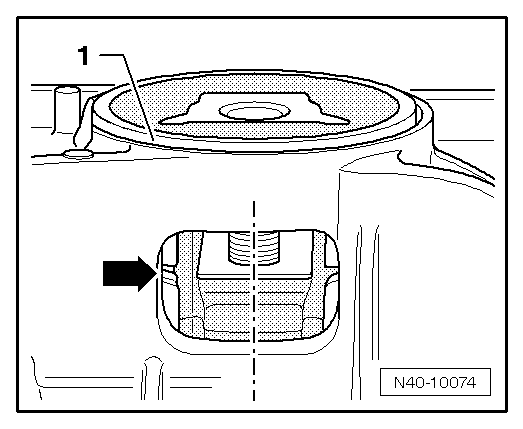

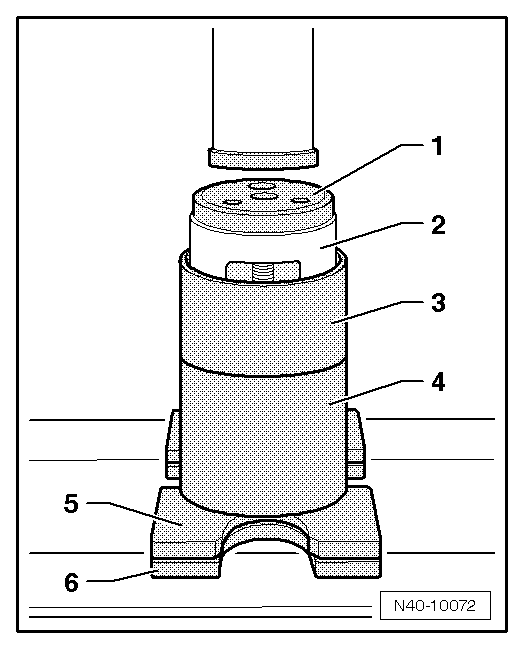

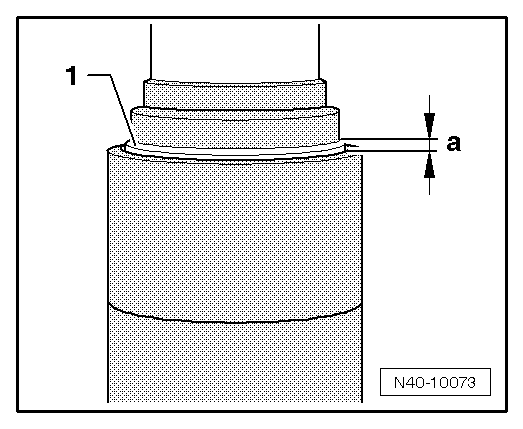

| The outside diameter -1- of both rubber-metal bearings must protrude up to 2 mm beyond the edge in the area of the opening for the pendulum support. |

| l

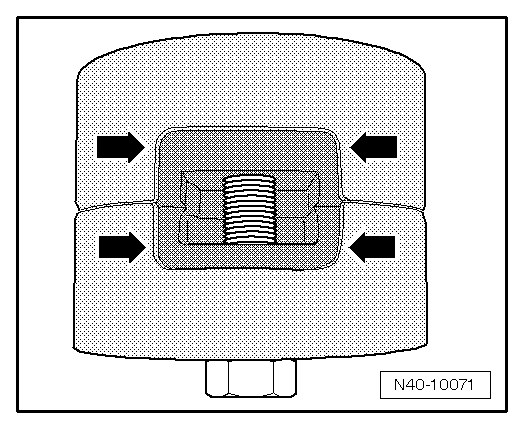

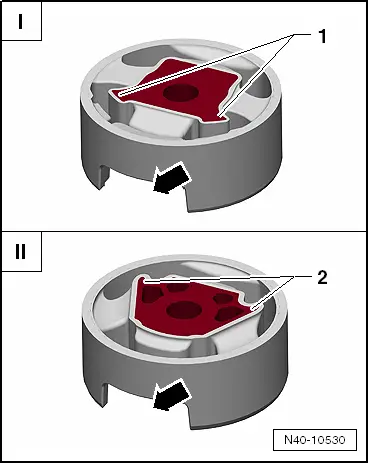

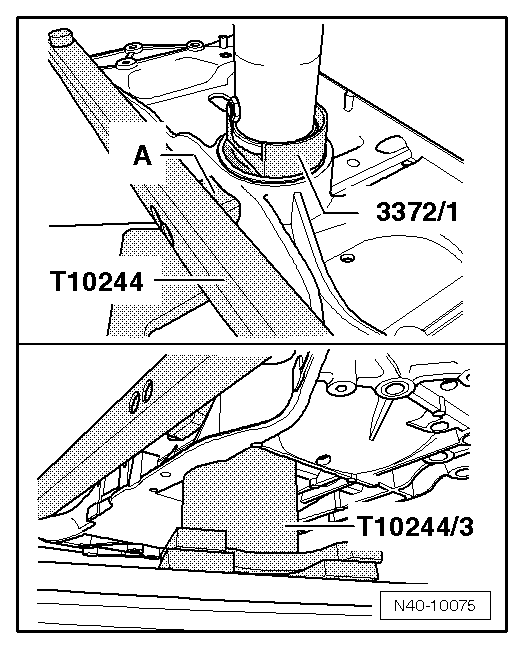

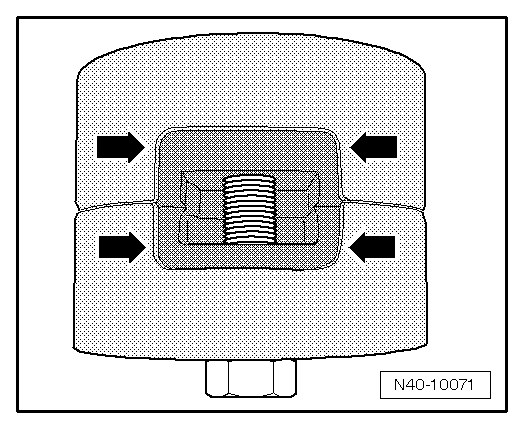

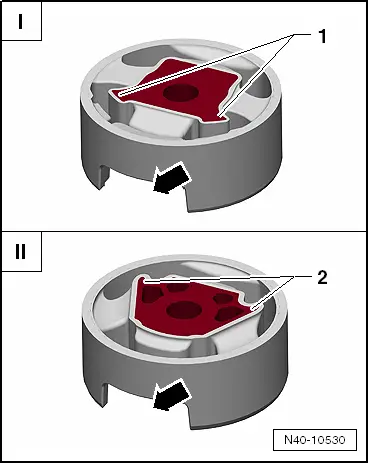

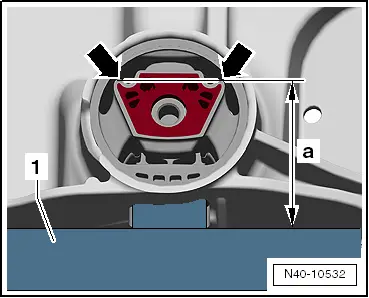

| The cutouts of the rubber-metal bearing must be centered in the opening of the assembly carrier. |

| l

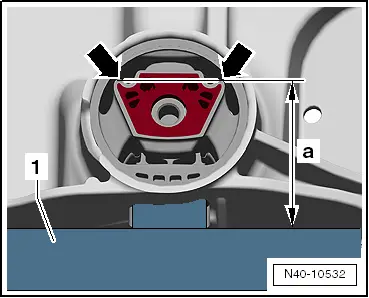

| A gap -arrow- between the rubber-metal bearings is allowed. |

| –

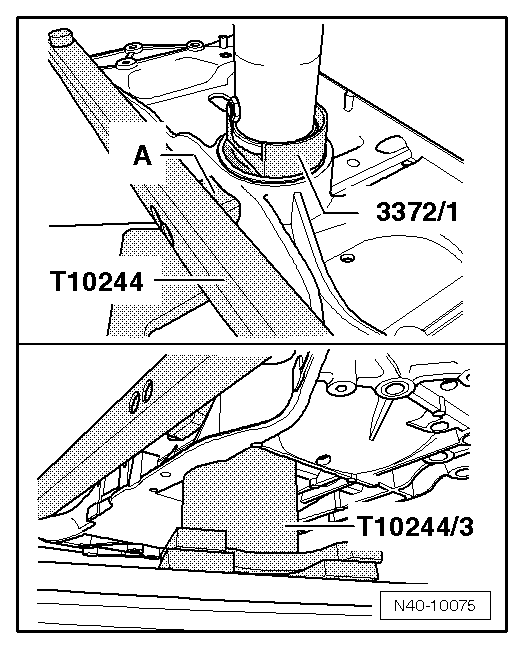

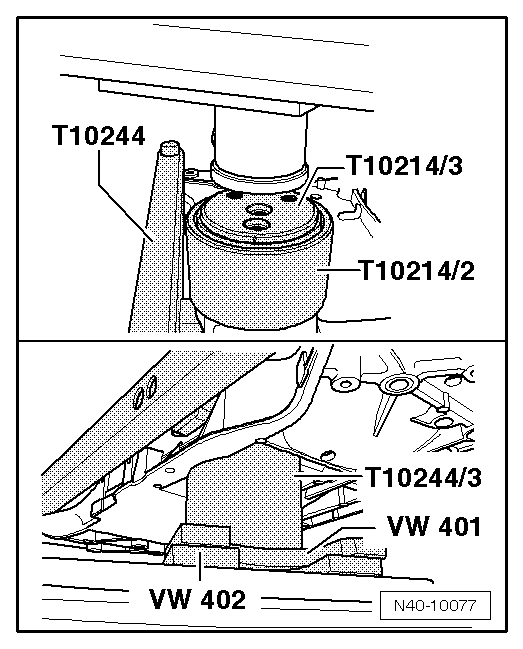

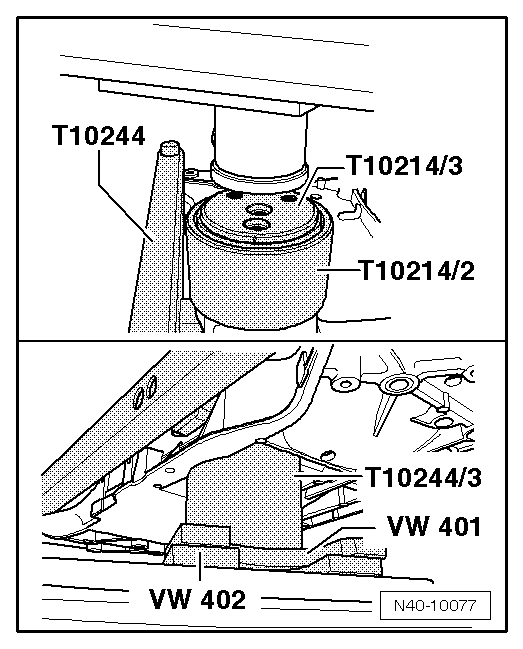

| Install assembly carrier. |

| –

| Check the steering wheel position during the test drive. |

Note | If after the test drive and with the wheels pointing straight ahead the steering wheel is off straight, perform a chassis alignment → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note