| –

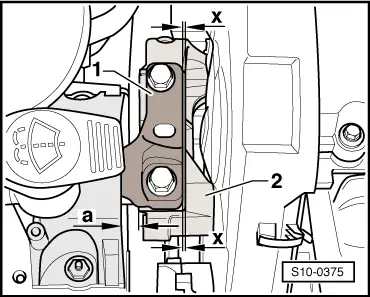

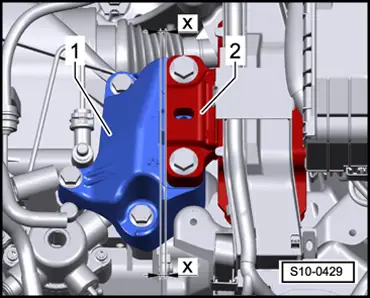

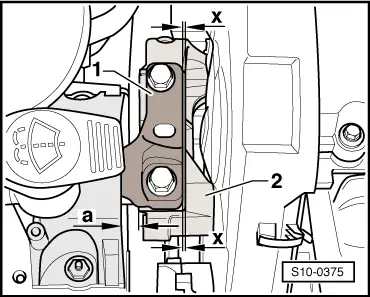

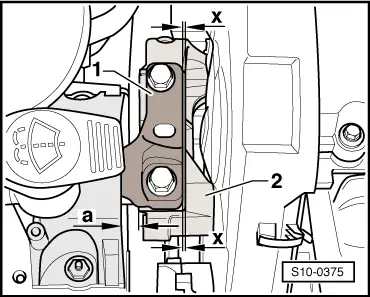

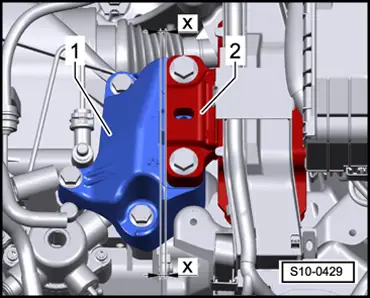

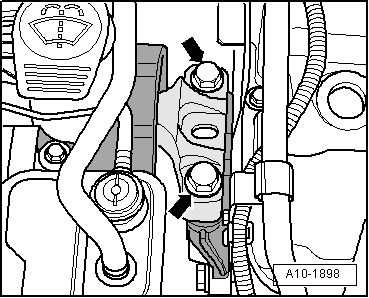

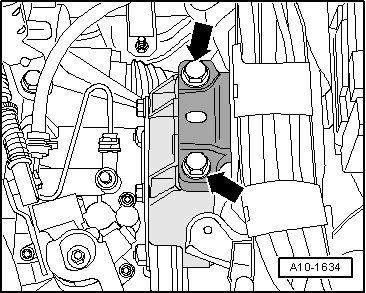

| Move the engine/gearbox unit with an assembly lever between engine support -2- and supporting arm -1- for engine mount until the following dimensions are set: |

| l

| Between engine bracket and engine support there must be a distance -a- of 10 mm. |

| l

| The cast iron edge on the engine support -2- must be parallel to the supporting arm -1- the dimension -x- must be the same at the front and rear. |

Note | The distance -a- = 10 mm can be checked e.g. with suitable round bars. |

| –

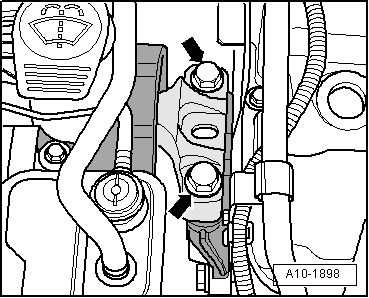

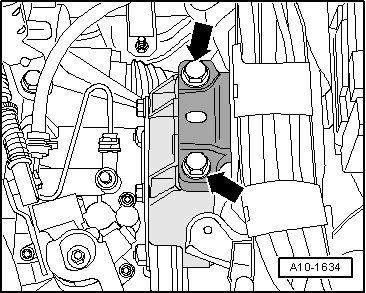

| Tighten the screws for the engine side assembly bracket → Chapter. |

|

|

|

Note

Note

Note

Note