Octavia Mk2

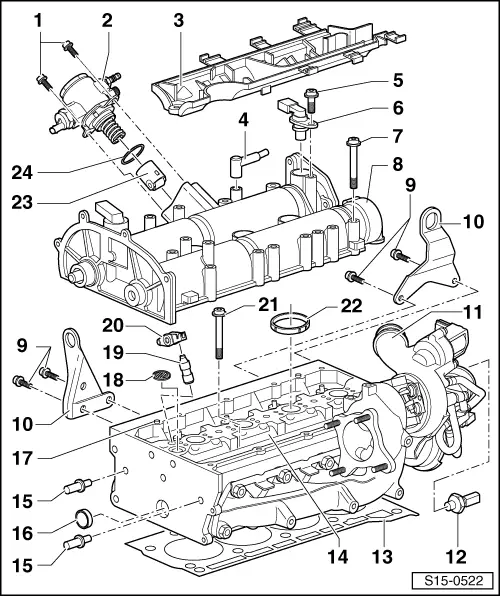

| Summary of components |

| Testing compression pressure → Chapter. |

Note

Note| t | When installing a replacement cylinder head, all the contact surfaces between the supporting elements, roller rocker arms and the cam tracks must be oiled before installing the camshaft housing. |

| t | Do not remove the plastic bases supplied as a protection for the open valves until just before fitting on the cylinder head. |

| t | If the cylinder head is replaced, also the entire coolant must be replaced. |

| t | Before assembly moisten all bearing and contact surfaces with oil. |

| t | Removing and installing intake manifold → Chapter. |

| 1 - | 8 Nm |

| 2 - | High pressure pump |

| q | for fuel supply |

| q | with fuel pressure regulating valve -N276 - |

| q | removing and installing → Chapter |

| 3 - | Guide |

| q | Screwed onto camshaft housing to 8 Nm |

| 4 - | to air filter |

| 5 - | 10 Nm |

| 6 - | Hall sender -G40- |

| q | with O-ring |

| q | replace the O-ring if it is damaged |

| 7 - | 10 Nm + torque a further 1/4 turn (90°) |

| q | replace |

| q | unscrew from the outside to the inside → Chapter |

| q | tighten from the inside to the outside → Chapter |

| 8 - | Camshaft housing |

| q | removing and installing → Chapter |

| 9 - | 20 Nm |

| 10 - | Lifting eye |

| 11 - | Exhaust gas turbocharger |

| q | removing and installing → Chapter |

| 12 - | Oil pressure switch -F1-, 25 Nm |

| q | check → Chapter |

| q | Cut open gasket ring if leaking and replace |

| 13 - | Cylinder head gasket |

| q | replace |

| q | metal gasket |

| q | after replacing fill entire system with fresh coolant |

| 14 - | Cylinder head |

| q | removing and installing → Chapter |

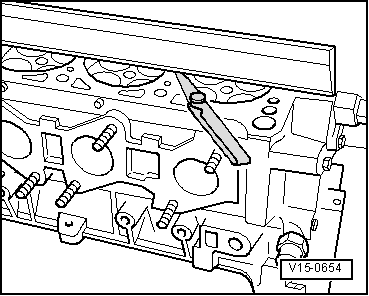

| q | check for distortion → Fig. |

| q | Sealing surfaces to the camshaft housing must be free of oil and grease. |

| q | after replacing fill entire system with fresh coolant |

| 15 - | Guide bolt |

| q | Tightening torque: 20 Nm |

| 16 - | Screw cap |

| q | replace if leaking |

| Removing: |

| – | Pierce through the centre using an expanding mandrel and pull out as straight as possible using a suitable tool. |

| Make sure the sealing surface on the cylinder head is not damaged. |

| Installing: |

| – | Thoroughly clean the sealing surface in the cylinder head |

| – | Thinly coat the new screw cap sideways all around with sealant -D 154 102 A1-. |

| – | Drive screw cap with drift pin e.g. pressure plate -MP 3-410 (VW 434)- straight into the hole. |

| l | The finishing edge of the screw cap must be approx. 1 mm deep in relation to the end face of the cylinder head. |

| – | Wipe off any sealant oozing out. |

| 17 - | Fit pin |

| 18 - | Oil filter |

| q | inserted into the cylinder head |

| q | replace |

| 19 - | Supporting element |

| q | do not interchange |

| q | with hydraulic valve clearance compensation |

| q | oil contact surfaces |

| 20 - | Roller rocker arm |

| q | inspect roller bearings for smooth operation |

| q | oil contact surfaces |

| q | to install clip onto the supporting element with the locking clips |

| 21 - | Cylinder head bolt |

| q | replace |

| q | observe the mounting instructions and sequence for loosening and tightening → Chapter |

| 22 - | Sealing ring |

| q | replace |

| q | 4 pieces |

| q | inserted into the cylinder head |

| 23 - | Roller tappet |

| q | Lightly moisten the contact surface with engine oil |

| 24 - | O-ring |

| q | replace |

| q | moisten with oil before inserting |

|

|