| –

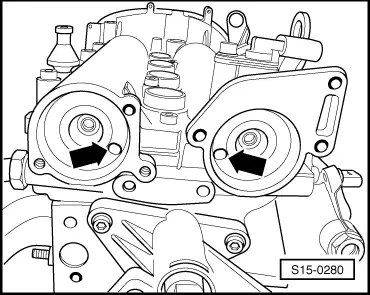

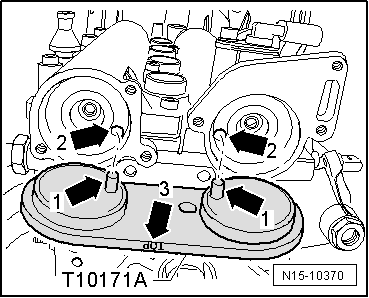

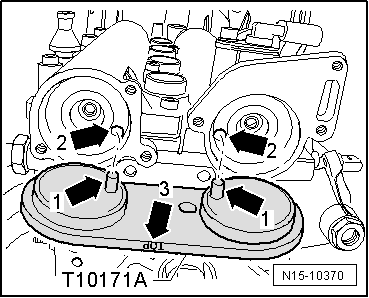

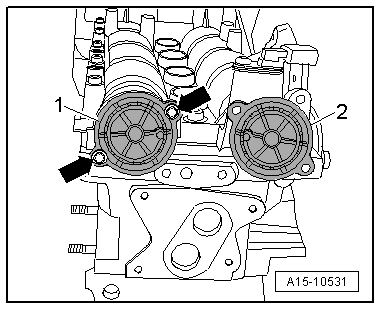

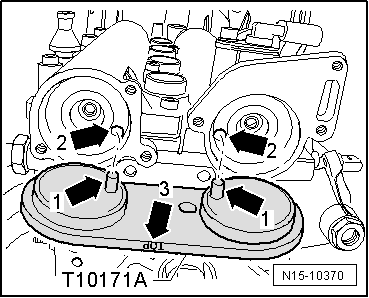

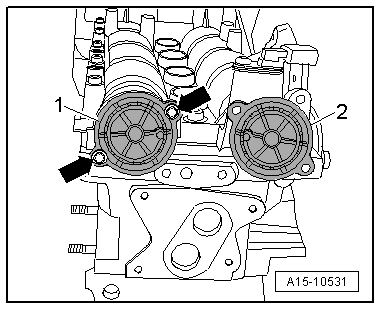

| Insert camshaft fixer/locator -T10171 A - up to the stop into the holes in the camshaft housing. |

| l

| The locking bolts -arrows 1- must engage in the holes -arrows 2-. The inscription “TOP”-arrow 3- must be legible from above. |

| If the camshaft fixer/locator -T10171 A- is not insertable up to the stop in the camshaft openings, the timing is not correct and must be set → Chapter. |

| The timing is O.K., if the camshaft fixer/locator -T10171 A- can be inserted up to the stop into the camshaft openings. |

| Further installation occurs in a similar way in reverse order to removal. Pay attention to the following: |

| t

| Replace the gasket rings for the caps of the camshafts and oil before assembly. |

|

|

|

Note

Note

Note

Note