| –

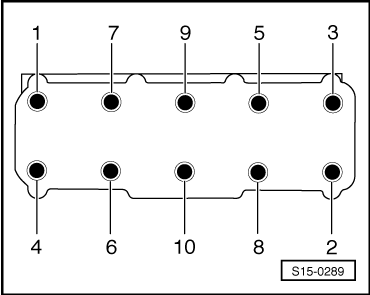

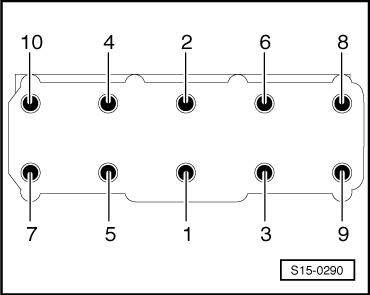

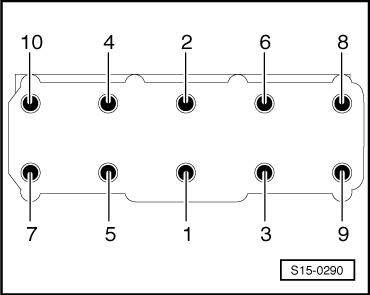

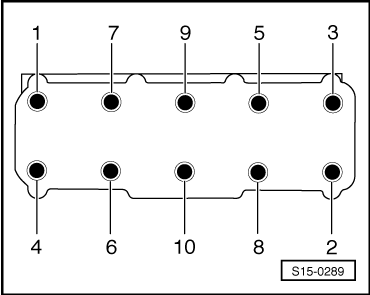

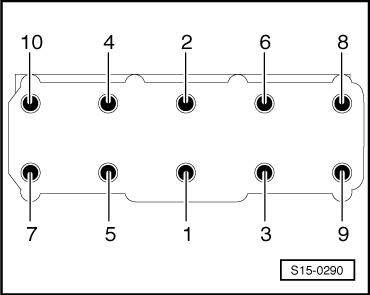

| Tighten cylinder head bolts in the tightening order shown as follows: |

| t

| Tighten all screws to 30 Nm. |

| t

| Then, torque all bolts further to 90° (1/4 turn) with a rigid wrench. |

| t

| Finally, once again turn all bolts through a further 90° (1/4 turn). |

| –

| Insert the supporting elements in the cylinder head and position the relevant roller rocker arm on the valve stem ends or supporting elements. |

| Further installation occurs in a similar way in reverse order to removal. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note