| –

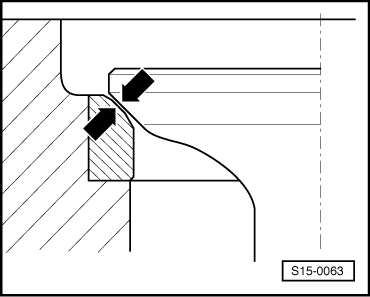

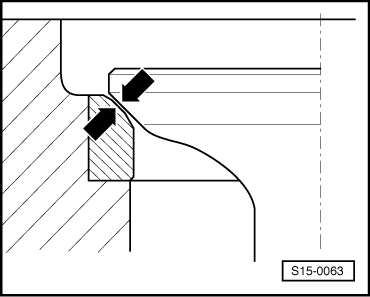

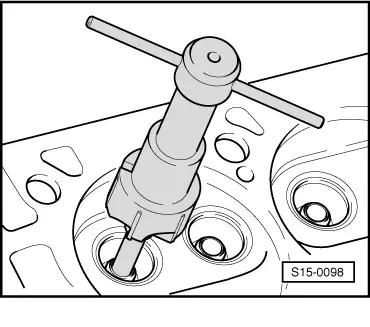

| Grind in valve/valve seat -arrows- with fine grinding paste so as to achieve a perfect contact pattern. |

| –

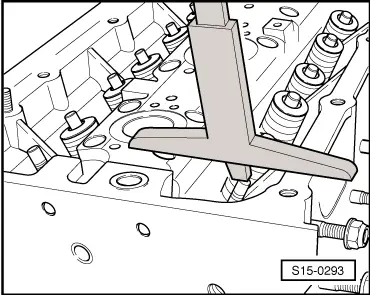

| Check contact pattern e.g. with water colour (perfect contact pattern over entire circumference). |

| –

| Check valves for tightness. |

| The tightness of the valves can be checked by filling petrol into the inlet and outlet canal (no petrol must flow out at the valve seat) |

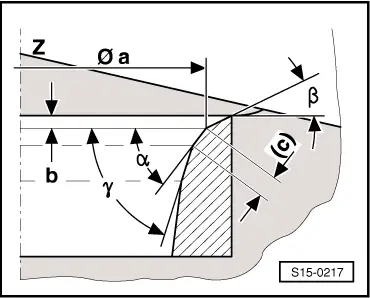

| After completing the repair measure once again the distances between the valve stem ends and the upper face of the cylinder head and calculate the maximum permissible reworking dimension. |

Note | If the maximum permissible reworking dimension is exceeded, proper operation of the valve gear is no longer assured and the cylinder head must be replaced. |

|

|

|

Note

Note