Octavia Mk2

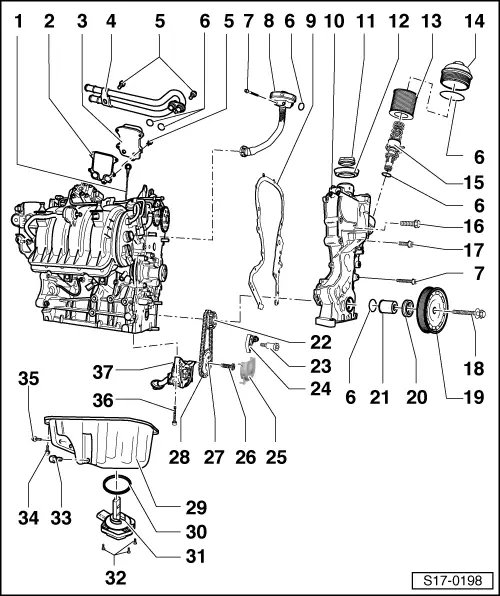

| Summary of components |

| The oil pressure switch -F1- is located in the front left of the cylinder head; removing and installing → Chapter. |

| 1 - | Dipstick |

| q | oil level must not exceed max. marking! |

| 2 - | Gasket |

| q | replace |

| 3 - | Oil cooler |

| 4 - | Coolant pipes |

| q | for oil cooler |

| 5 - | 8 Nm |

| 6 - | O-ring |

| q | replace |

| 7 - | 10 Nm |

| 8 - | Pressure control valve (PCV valve) |

| q | with ventilation hose |

| 9 - | Gasket |

| q | replace |

| 10 - | Timing case |

| q | removing and installing → Chapter |

| 11 - | Screw cap |

| q | Replace seal if damaged |

| 12 - | Gasket ring |

| q | replace if damaged |

| 13 - | Filter insert |

| 14 - | Oil filter cover, 25 Nm |

| 15 - | Valve |

| q | with short circuit valve |

| Opening pressure: 0.25 MPa (2.5 bar) excess pressure |

| q | with return-flow check valve |

| 16 - | 50 Nm |

| 17 - | 10 Nm |

| q | M6x22 mm |

| 18 - | Fixing screw |

| q | for crankshaft - belt pulley |

| q | replace |

| q | The clamping surface of the fixing screw must be free of grease and oil. |

| q | insert oiled (thread) |

| q | tighten → Chapter |

| 19 - | Crankshaft-belt pulley |

| q | The clamping surfaces of the crankshaft belt pulley must be free of grease and oil. |

| q | Removing and installing ribbed V-belt → Chapter |

| 20 - | Gasket ring for crankshaft in timing case |

| q | replace → Chapter |

| 21 - | Bushing |

| q | replace with repair set → Chapter |

| q | The clamping surfaces of the bushing must be free of grease and oil. |

| 22 - | Sprocket |

| q | for oil pump drive |

| q | removing and installing → Chapter |

| 23 - | 15 Nm |

| 24 - | Chain tensioner with tensioning rail and tensioning spring |

| q | for oil pump drive |

| q | Tightening torque: 15 Nm |

| q | only be replaced as a complete unit |

| 25 - | Cover |

| q | for chain sprocket of the oil pump |

| q | clipped into the oil pump housing |

| 26 - | 20 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 27 - | Sprocket |

| q | for oil pump |

| q | Counterhold sprocket with counterholder -T10172- |

| 28 - | Drive chain |

| q | for oil pump |

| q | mark running direction (installed position) before removing |

| q | removing and installing → Chapter |

| 29 - | Oil pan |

| q | removing and installing → Chapter |

| 30 - | Gasket ring |

| q | replace |

| q | oil before the assembly |

| 31 - | Oil level and oil temperature sender -G266 - |

| q | replace if damaged |

| q | check → Current flow diagrams and Fitting locations |

| 32 - | 10 Nm |

| 33 - | Oil drain plug, 30 Nm |

| q | with captive seal |

| q | replace |

| 34 - | 13 Nm |

| q | replace |

| q | Slacken and tighten the bolts at the gearbox side with socket insert - T10058- |

| 35 - | 40 Nm |

| 36 - | 25 Nm |

| 37 - | Oil pump |

| q | must be replaced completely |

| q | removing and installing → Chapter |