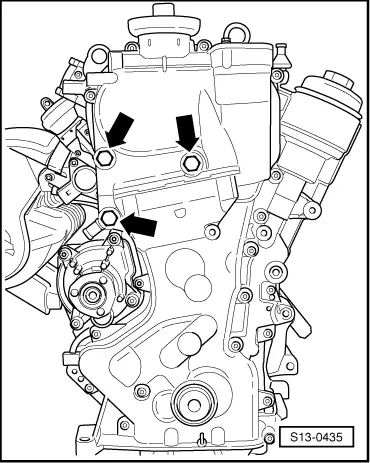

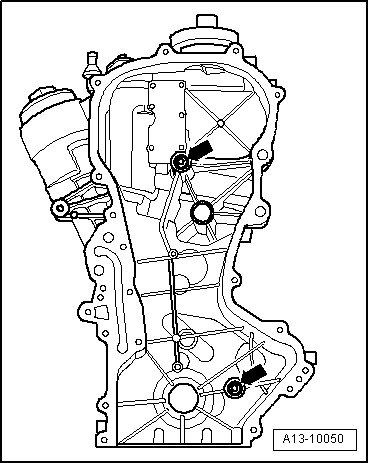

| Removing and installing the timing case |

| Special tools and workshop equipment required |

| t

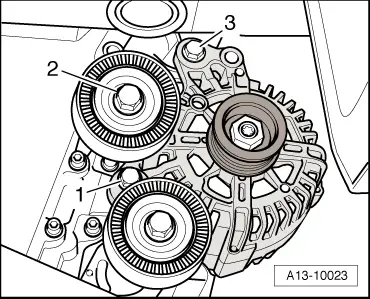

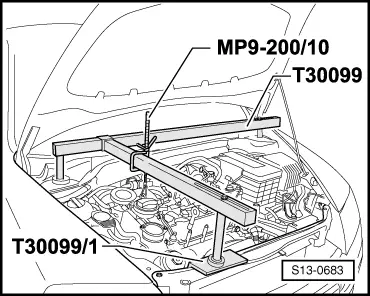

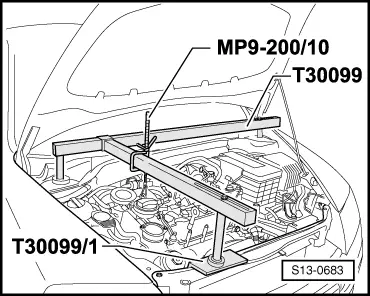

| Supporting device -T30099- |

| t

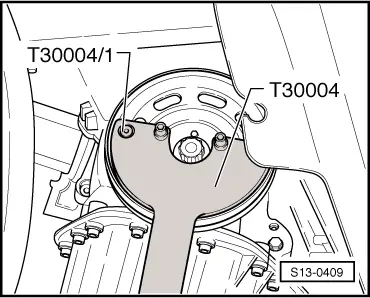

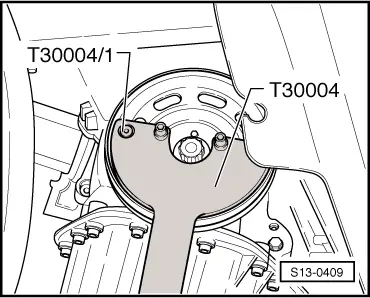

| Counterholder -T30004 (3415)- |

| t

| Bolt -T30004/1 (3415/1)- |

| t

| Hook for MP9-200 and T30099 -MP9-200/10 (10-222A/10) - |

| t

| Catch pan for workshop crane, e.g. -VAS 6208- |

| t

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning agent and grease remover e.g. -D 000 401 04- |

| –

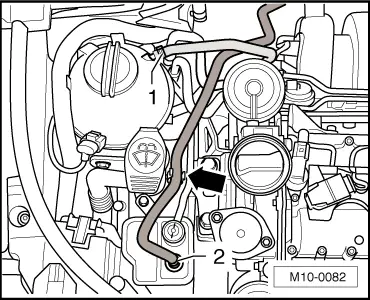

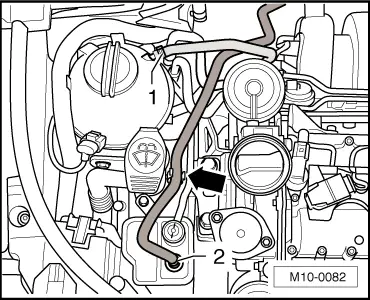

| Remove engine cover with air filter → Chapter. |

| –

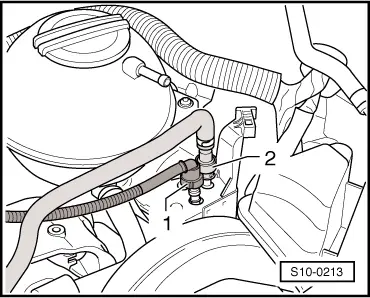

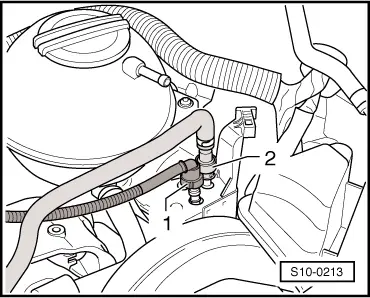

| Unscrew pressure control valve (PCV valve). |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note