| Special tools and workshop equipment required |

| t

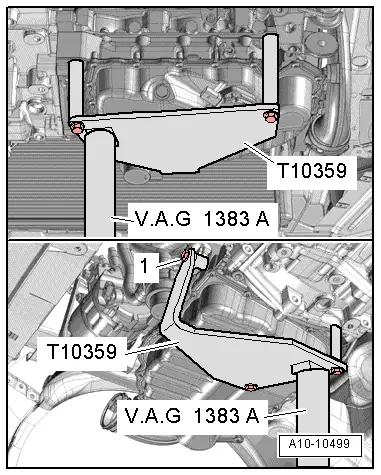

| Engine/gearbox jack, e.g. -V.A.G 1383 A- |

| t

| Double ladder, e. g. -VAS 5085- |

| t

| Removal tool for inner lining of the door panel -MP8-602/1 - |

| t

| Pliers for spring strap clamps |

| t

| Catch pan e.g. -VAS 6208 - |

Note | t

| The engine is removed downwards together with the gearbox. |

| t

| All cable straps that have been loosened or cut open when the engine was removed must be fitted again in the same location when the engine is installed again. |

| t

| Collect drained coolant in a clean container for reuse or proper disposal. |

Caution | When undertaking all installation work, particularly in the engine compartment because of its cramped construction, please observe the following: |

| t

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, the active charcoal container-unit, cooling fluid and refrigerant, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| In order to avoid damage to the cables, ensure that there is adequate free access to all moving or hot components. |

|

| Observe all safety measures and notes for assembly work on the fuel, injection and ignition system and the charge air system as well as rules for cleanliness → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING