| Special tools and workshop equipment required |

| t

| Supporting device -T30099- |

| t

| Hook for T30099 -MP9-200/10 (10-222A/10)- |

Note | t

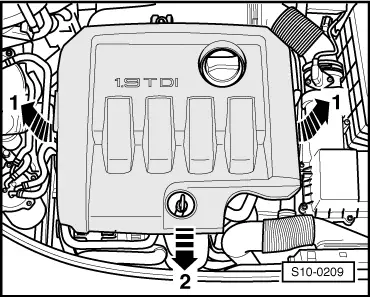

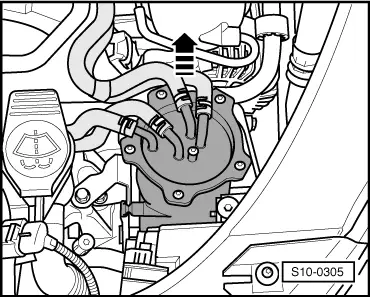

| The engine is removed downwards together with the gearbox. |

| t

| All cable straps that have been loosened or cut open when the engine was removed must be attached again in the same location when the engine is installed again. |

| t

| Collect drained coolant in a clean container for proper disposal or reuse. |

Caution | When undertaking all installation work, particularly in the engine compartment because of its cramped construction, please observe the following: |

| t

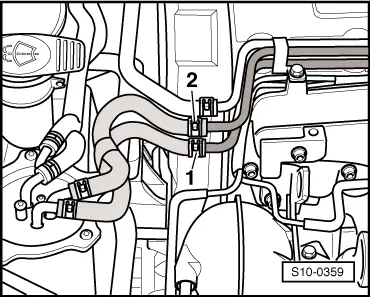

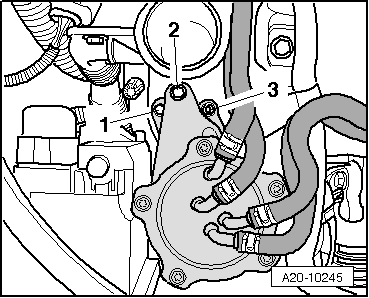

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling fluid and refrigerant, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| In order to avoid damage to the cables, ensure that there is adequate free access to all moving or hot components. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING