| l

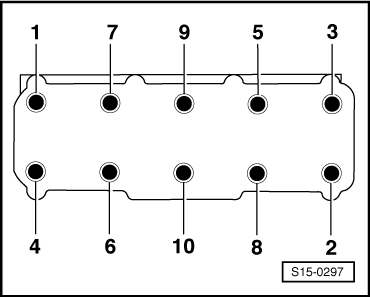

| Engine temperature should not exceed 35°C, because the cylinder head could be twisted when slackening the screws. |

| l

| The pistons must not be in TDC. |

| –

| Switch off ignition and withdraw ignition key. |

| –

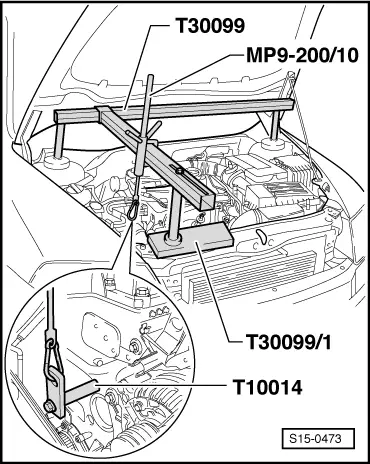

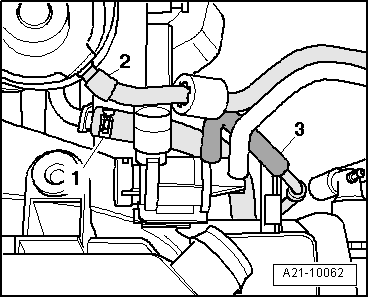

| Remove air filter, charge air pipes and charge air hoses → Chapter. |

| t

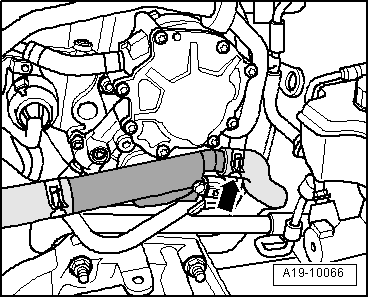

| Engine identification characters BJB, BKC, BXE → Chapter. |

| t

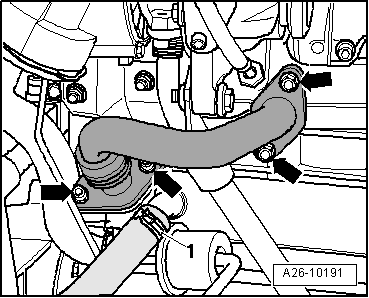

| Engine identification characters BLS → Chapter. |

| –

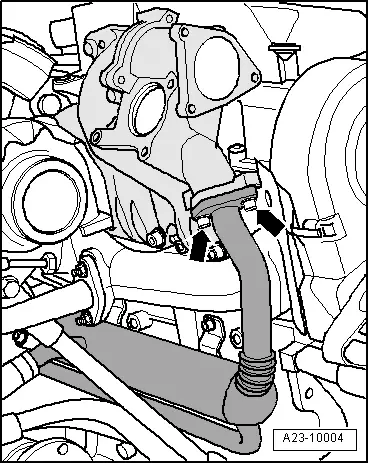

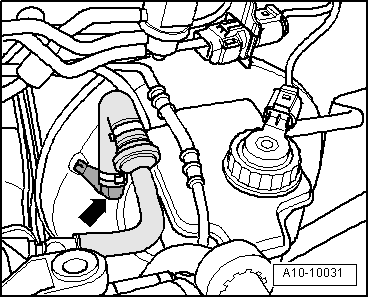

| Position drip tray e.g. -VAS 6208 - under the engine. |

WARNING | Hot steam or hot coolant may escape when the compensation bottle is opened. Cover the cap with a cloth and open carefully. |

|

|

|

|

Note

Note Note

Note

Note

Note Note

Note