| Replacing the valve stem seals on the installed cylinder head (Superb II, Octavia II, Fabia II, Roomster) |

| Special tools and workshop equipment required |

| t

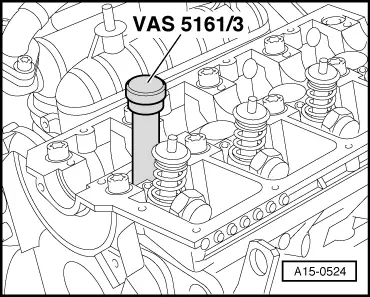

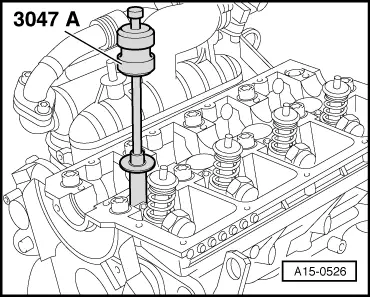

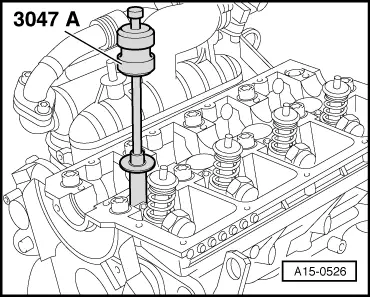

| Valve stem seal extractor -MP1-206 (3047 A)- |

| t

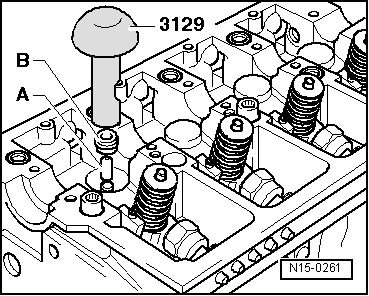

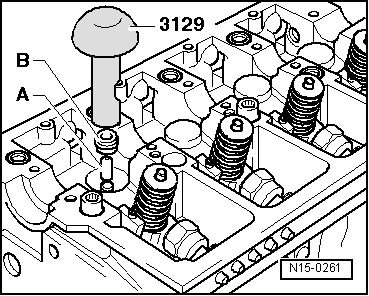

| Valve stem seal insertion tool -MP1-212 (3129)- |

| t

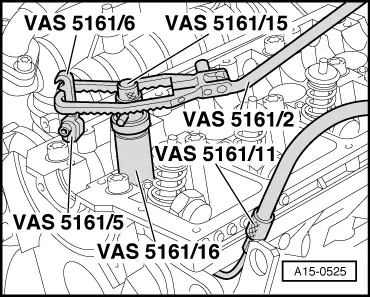

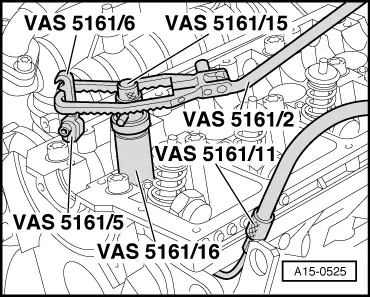

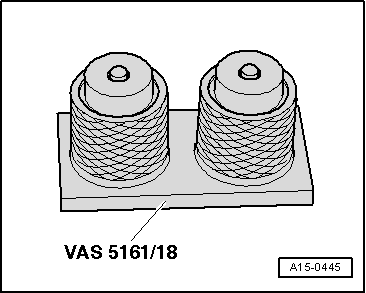

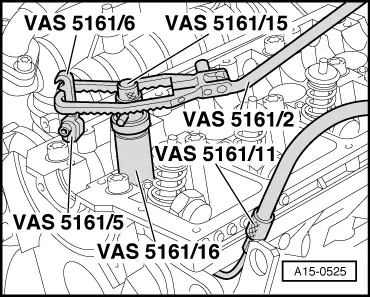

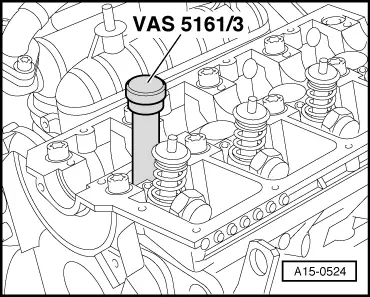

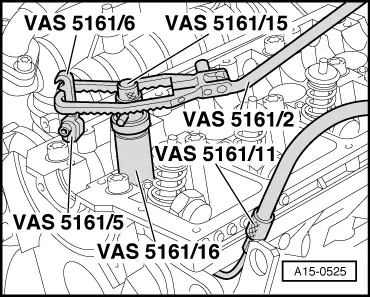

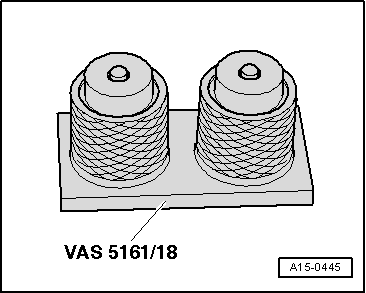

| Disassembly and assembly device for valve collets -VAS 5161- |

Note | t

| On engines with identification characters BJB, BLS and BXE, those ceramic glow plugs which are marked with a white or silvery painted gasket ring can be installed. |

| t

| Metal glow plugs have a red or green gasket ring. |

Caution | Pay attention to safety instructions when handling ceramic glow plugs → Chapter. |

|

| –

| Remove bearing shells of camshaft from the cylinder head. |

Note | t

| Do not exchange the used bearing shells of the camshaft, mark them for reinstalling. |

| t

| When installing again, mark the assignment of the hydraulic bucket tappets. |

| –

| Remove the hydraulic bucket tappets from the cylinder head and place on a clean surface with the contact surface facing down. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note