| –

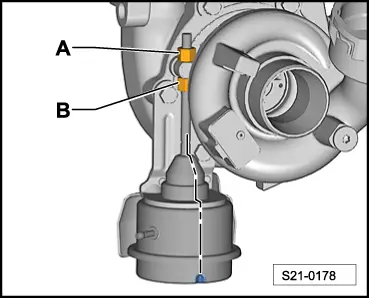

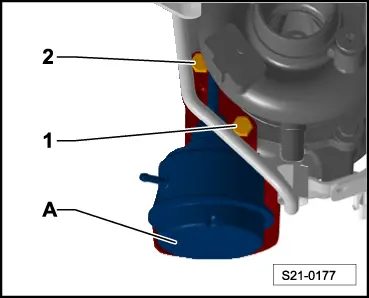

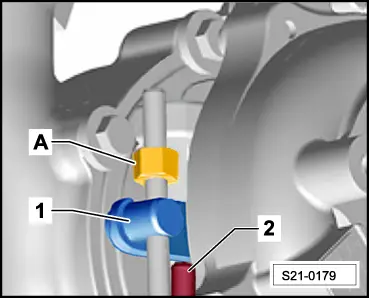

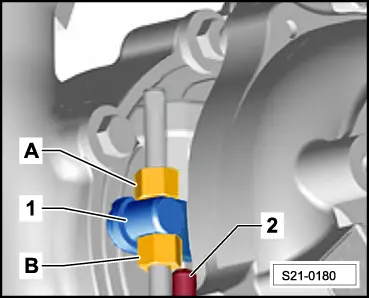

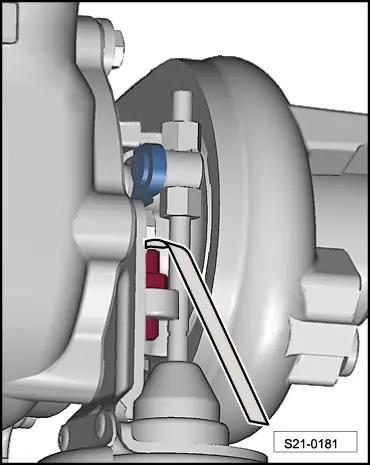

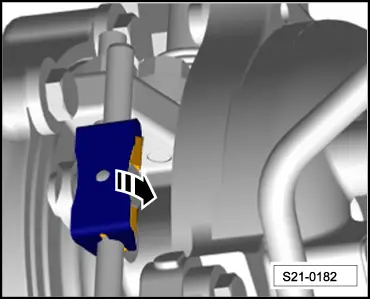

| Mark the opposite position of the pressure box of the vacuum setting element and the control rod in the released position, as shown, in different colours. |

Note | The colour marking makes it possible to check the opposite position of the pressure box of the vacuum setting element and the control rod once more after tightening both nuts on the control rod and, if necessary, to correct any twisting. |

Caution | Only use new screws and nuts from the spare part set. |

|

| –

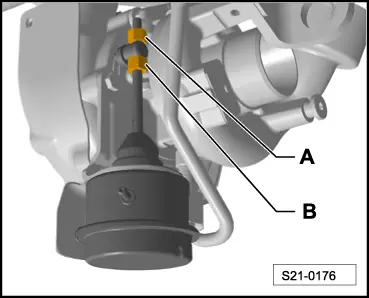

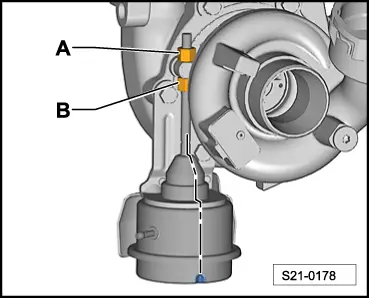

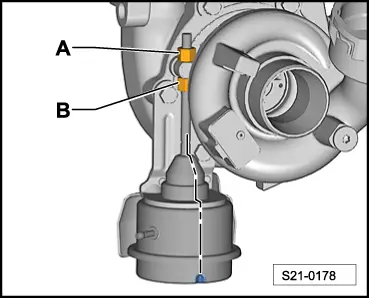

| If necessary, remove the fixing nut from the control rod of the new vacuum setting element. |

| –

| Screw the counternut onto the control rod of the new vacuum setting element by hand up to the thread end and pull the control rod through the opening of the adjusting lever on the exhaust gas turbocharger. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution