Octavia Mk2

| Summary of components |

Note

Note| If considerable quantities of metal swarf or abrasion is found in the oil or in the engine when carrying out repairs, this can be subject to damage to the crankshaft and conrod bearings. In order to avoid consequential damage, perform the following tasks when carrying out repairs: |

| – | Carefully clean the oil galleries. |

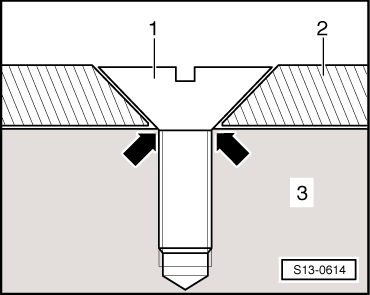

| – | Replace oil spray jets. |

| – | Replace oil cooler. |

| – | Replace oil filter element. |

| t | Before removing the crankshaft, ensure a suitable place is available for placing it down so that the sensor rotor (Pos. 4) does not rest on anything or get damaged. |

| t | Secure the engine with engine mount -MP1-202- on the assembly stand -MP9-101- before performing assembly work. |

| 1 - | 65 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | tighten thread |

| 2 - | Bearing caps |

| q | Bearing cap 1: belt pulley side |

| q | retaining lugs of the bearing shells of the cylinder block/bearing cap must be on top of one another |

| 3 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 4 - | Rotor |

| q | for engine speed sender -G28- |

| q | replace sensor rotor each time the bolts are slackened |

| q | assembly only possible in one position -holes offset- |

| q | removing and installing → Fig. |

| 5 - | Crankshaft |

| q | Axial play when new: 0.07…0.23 mm |

| Wear limit: 0.30 mm |

| q | Crankshaft bearing pins: Ø 54.00 mm |

| q | Conrod bearing: Ø 47.80 mm |

| 6 - | Thrust washers |

| q | for bearing 3 |

| 7 - | Bearing shells for cylinder block |

| q | with lubricating groove |

| q | do not mix up used bearing shells (mark) |

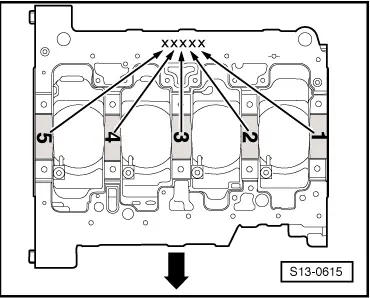

| q | Identification → Fig. |

| 8 - | Bearing shell for bearing cap |

| q | without lubricating groove |

| q | do not mix up used bearing shells (mark) |

| q | Identification → Fig. |

|

|

| Letter on the cylinder block | Colour of the support | |

| B | = | blue |

| G | = | yellow |

| W | = | white |

Note

Note

|