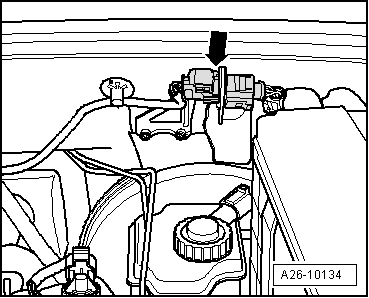

| –

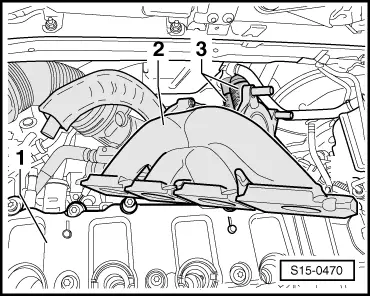

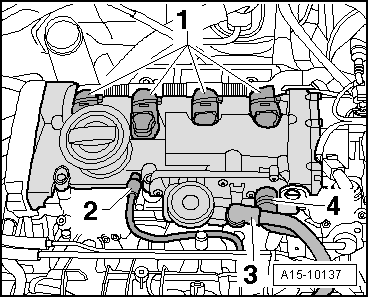

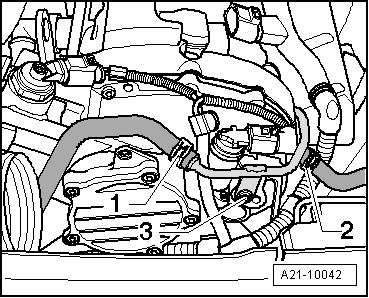

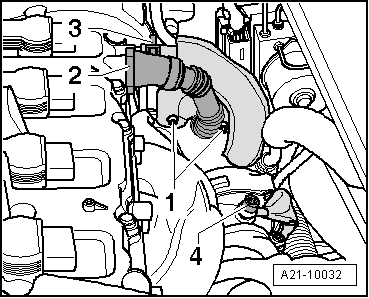

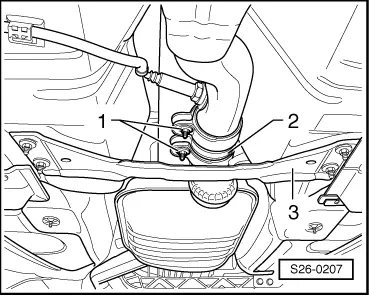

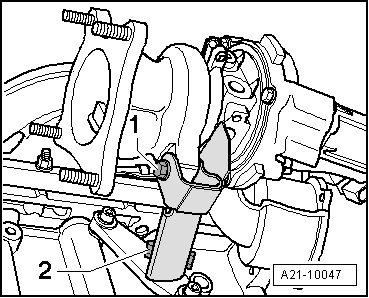

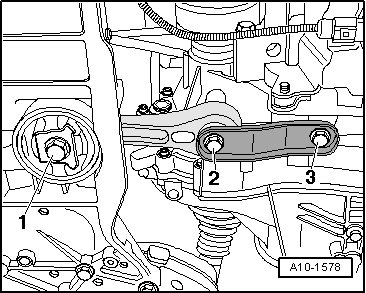

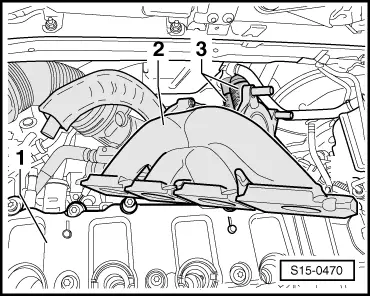

| Remove the exhaust gas turbocharger/exhaust manifold -2- between the coolant hoses -3- and the cylinder head cover -1- inclined to the top left. |

Caution | In case a mechanical damage to the exhaust gas turbocharger is found, e.g. damage to the compressor wheel, it is not sufficient to only replace the turbocharger. In order to avoid consequential damage, perform the following tasks: |

| t

| Change engine oil and oil filter. |

| t

| Inspect the air filter housing, the air filter element and the intake hoses for contaminations. |

| t

| Inspect the whole charge-air routing and the charge air cooler for foreign bodies. |

| If foreign bodies are detected in the charge air system, the complete charge-air routing must be cleaned and if necessary the charge air cooler must also be replaced. |

|

| Installation is carried out in the reverse order. Pay attention to the following: |

| t

| Gaskets, gasket rings and self-locking nuts must be replaced. |

| t

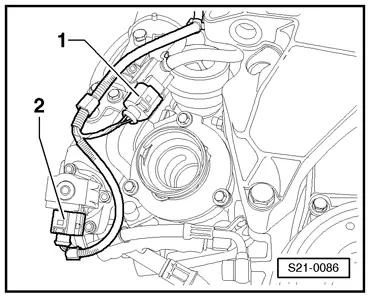

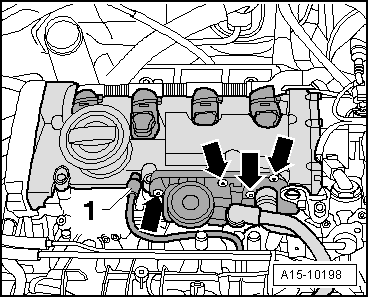

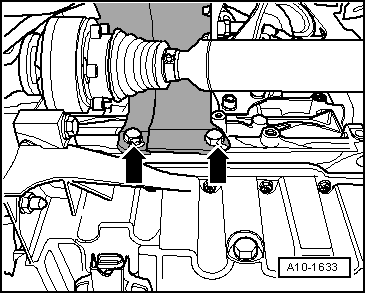

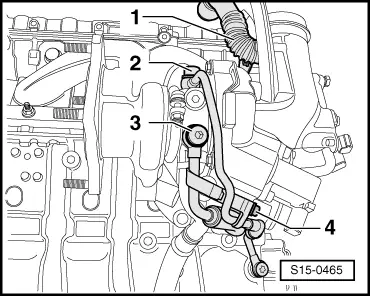

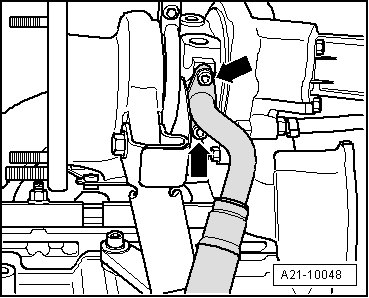

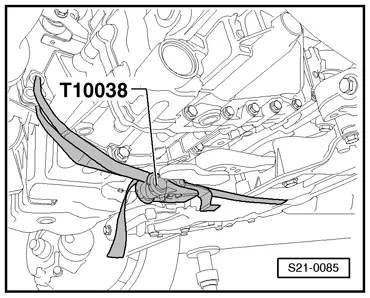

| Fill the exhaust turbocharger with engine oil at the connection fitting for the oil feed line. |

| t

| After installing the exhaust turbocharger, run engine at idling speed for about 1 minute to ensure that oil is supplied to the exhaust turbocharger. |

| t

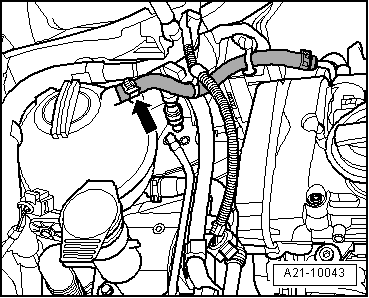

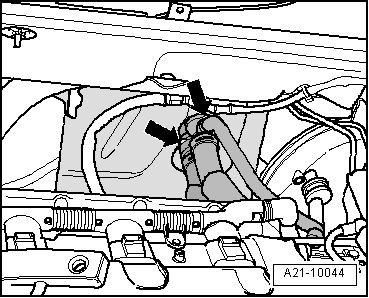

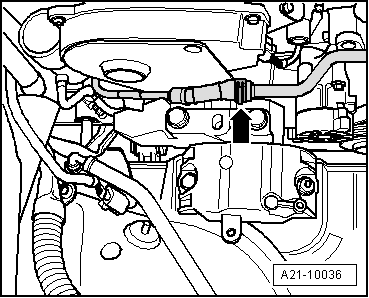

| The coolant return flow line ( → Chapter, Pos. 6) must be installed together with the exhaust turbocharger. |

| t

| Hose connections and hoses for charge air system must be free of oil and grease before being assembled. The gasket ring and the sealing surface must be slightly oiled only for push-fit couplings → Chapter. |

| t

| For this step, observe the assembly instruction for hose connections with push-fit couplings → Chapter. |

| –

| Install exhaust system and align free of stress → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution