| –

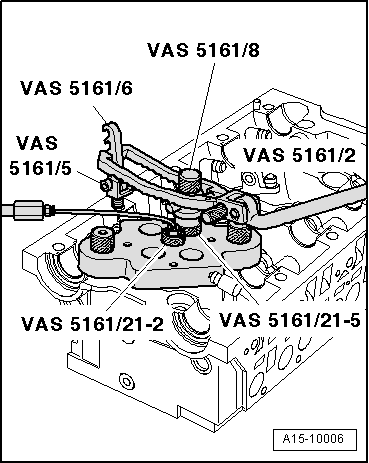

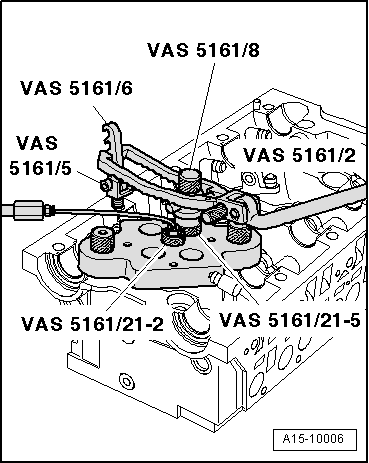

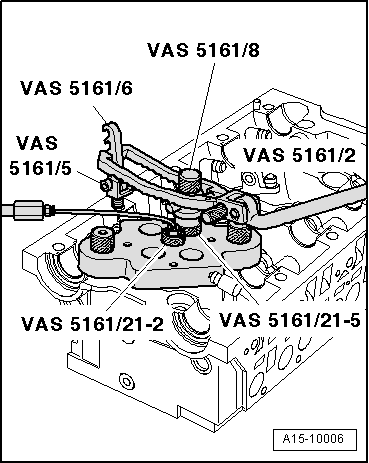

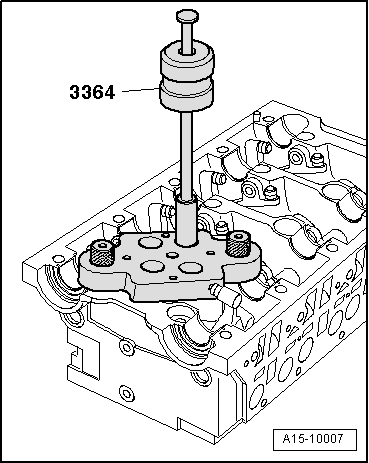

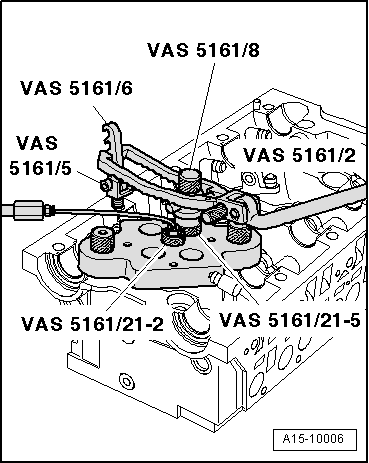

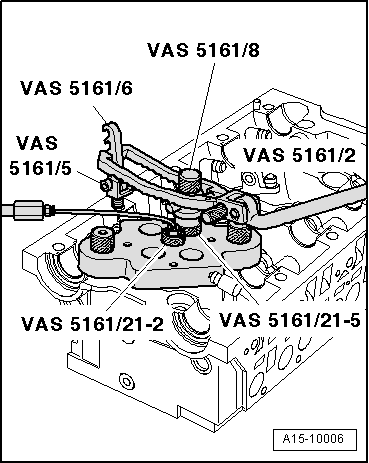

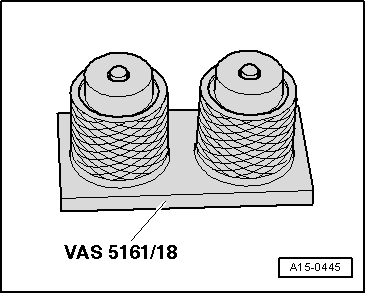

| Insert the assembly cartridge -VAS 5161/8- into the guide plate. |

| –

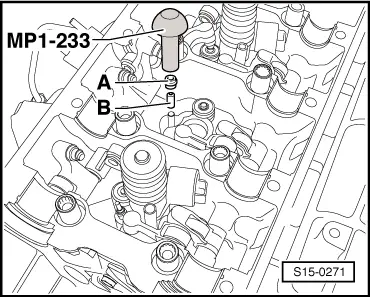

| Press down the pressure fork -VAS 5161/2-, turn the knurled screw of the assembly cartridge back and forward and while doing so pull it towards the top. Thereby the valve keys are replaced. |

| –

| Release the pressure fork -VAS 5161/2- on tightened knurled screw. |

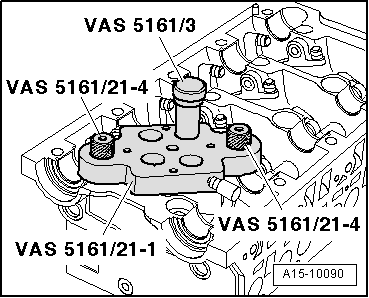

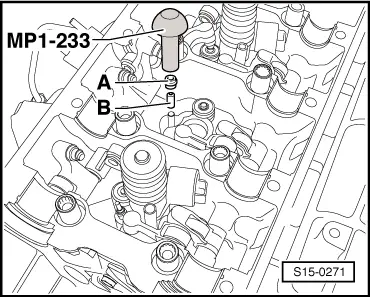

| The valve stem seal is removed and installed on the other valves in the same way. |

Note | t

| After installing the camshafts, the engine must not be cranked or started for about 30 minutes. Roller rocker arm with hydraulic valve clearance compensation must settle (otherwise valves would strike the piston). |

| t

| After carrying out work on the valve gear, carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note