| –

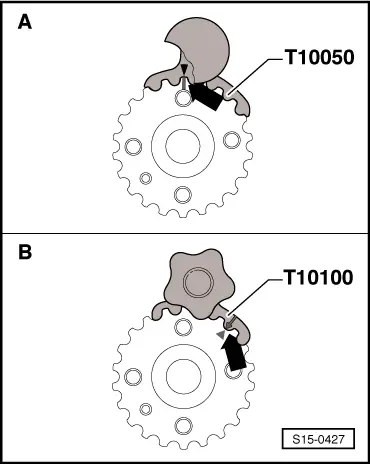

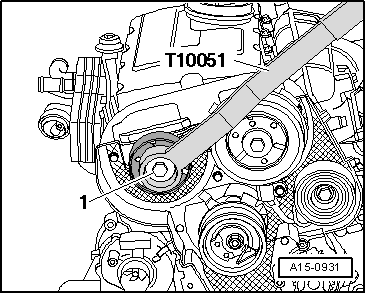

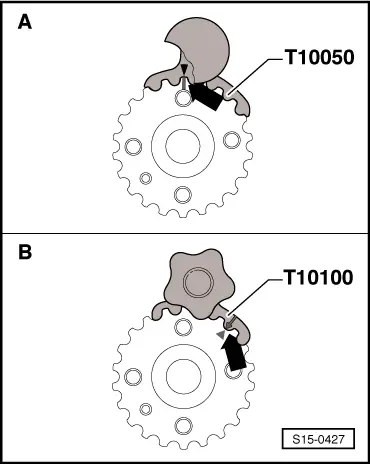

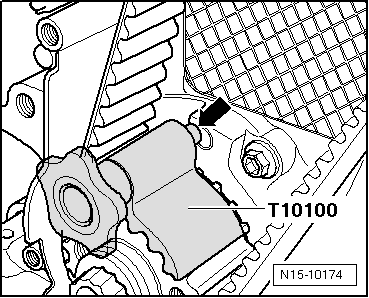

| Depending on the version of the toothed belt sprocket, lock the crankshaft with the crankshaft arrester -T10050- or the crankshaft arrester -T10100-. |

| Difference of the toothed belt sprocket of crankshaft: |

| A = original version of toothed belt sprocket with circular tooth flank, rectangular TDC marking for cylinder 1 at tooth in 12 o'clock position - use crankshaft arrester -T10050-. |

| B = new version of toothed belt sprocket with eliptical tooth flank, triangular TDC marking for cylinder 1 at tooth opening in 1 o'clock position - use crankshaft arrester -T10100-. |

Note | t

| The markings on the toothed belt sprocket and on the crankshaft arrester must be in line with each other -arrow-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING