Octavia Mk2

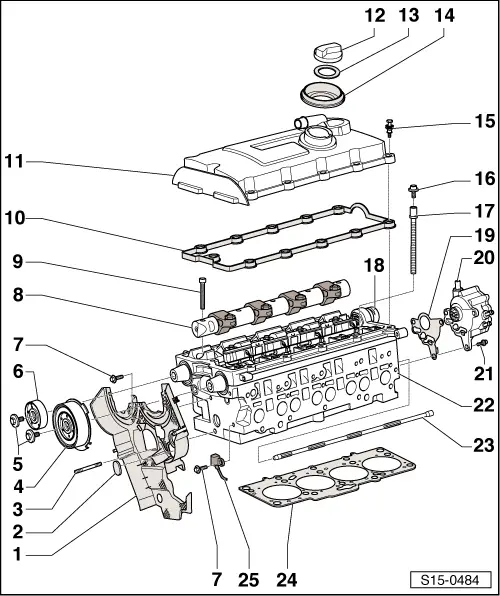

| Summary of components for engine with engine identification characters BKD, AZV |

| 1 - | Rear toothed belt guard |

| 2 - | Rubber grommet |

| q | replace if damaged |

| 3 - | Pin screw - 10 Nm |

| 4 - | Hub |

| q | for inlet camshaft with rotor for hall sender -G40- |

| q | to remove use extractor -T10052- |

| 5 - | 100 Nm |

| q | to release and tighten use counterholder -T10051- |

| 6 - | Hub |

| q | for exhaust camshaft |

| q | to remove use extractor -T10052- |

| 7 - | 10 Nm |

| q | insert using locking agent -D 000 600 A2- |

| 8 - | Valve-lever shaft |

| q | Mark the installation position of the valve lever |

| q | do not interchange |

| q | removing and installing → Chapter |

| q | before inserting, check whether all the ball studs and O-rings are inserted in the unit injectors |

| 9 - | 20 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | pay attention to order for slackening → Chapter |

| q | pay attention to order and procedure for tightening → Chapter |

| 10 - | Gasket for cylinder head cover |

| q | replace if damaged or leaking |

| q | press onto the spacer sleeves (Position 15) |

| 11 - | Cylinder head cover |

| q | removing and installing → Chapter |

| 12 - | Screw cap |

| 13 - | Gasket |

| q | replace if damaged or leaking |

| 14 - | Sealing sleeve |

| 15 - | Screw with spacer sleeve, 10 Nm |

| q | pay attention to sequence for loosening and tightening → Chapter |

| 16 - | 20 Nm |

| 17 - | Cylinder head bolt |

| q | replace |

| q | pay attention to order for slackening → Chapter |

| q | pay attention to order and procedure for tightening → Anchor |

| 18 - | Multipin plug connection |

| q | central for pump-nozzle units |

| q | when removing, disconnect plug connection from bushing by turning to the left |

| 19 - | Gasket |

| q | replace |

| 20 - | Tandem pump |

| q | removing and installing → Chapter |

| q | check → Chapter |

| 21 - | 20 Nm |

| 22 - | Cylinder head |

| q | removing → Chapter |

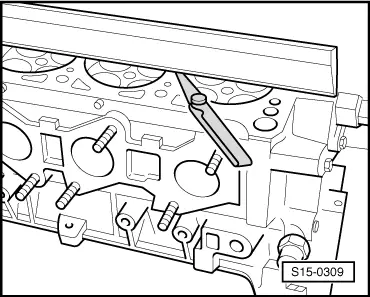

| q | check for distortion → Fig. |

| q | installing → Chapter |

| q | after replacing fill entire system with fresh coolant → Chapter |

| 23 - | Mixing tube |

| q | inserted into cylinder head |

| q | pull out with hook |

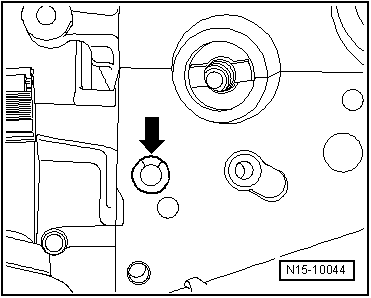

| q | Fitting position mixing tube → Fig. |

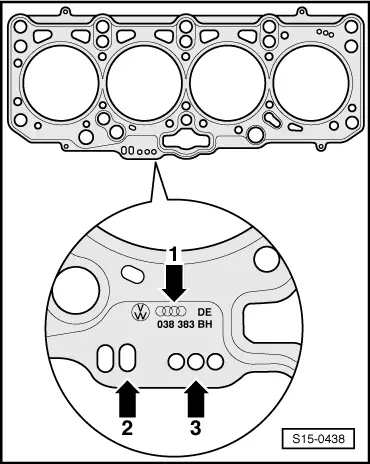

| 24 - | Cylinder head gasket |

| q | replace → Chapter |

| q | Pay attention to the marking → Fig. |

| 25 - | Hall sender -G40- |

| q | for camshaft position |

|

|

Note

Note

|

|