| –

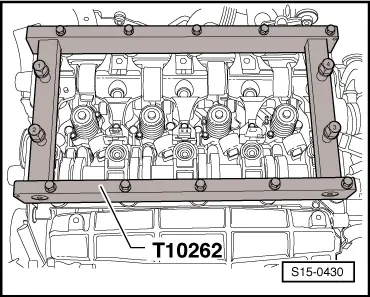

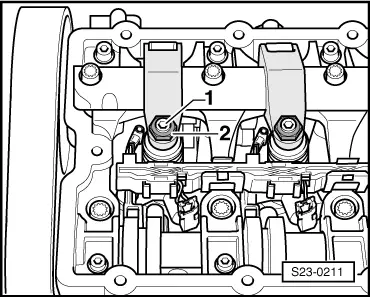

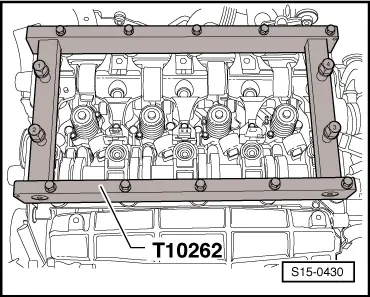

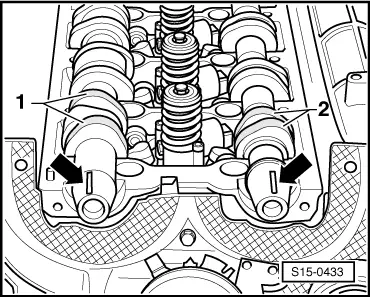

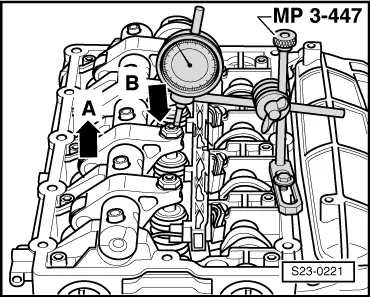

| Position frame -T10262-, as shown, on the bearing frame and tighten fixing screws SW 10 to 10 Nm. |

| –

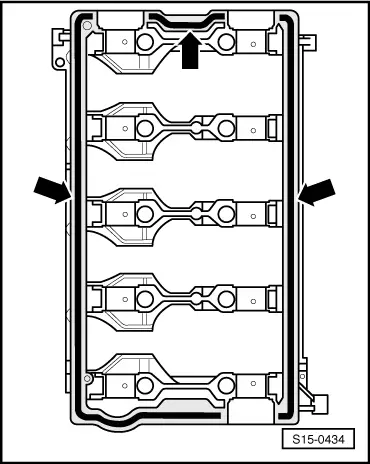

| Screw in press-off screws by hand, until these touch the cylinder head screws. |

| –

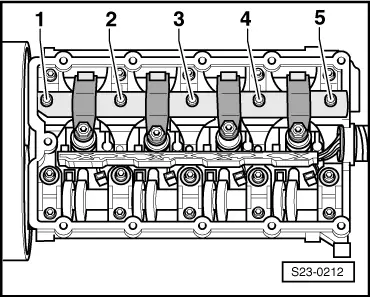

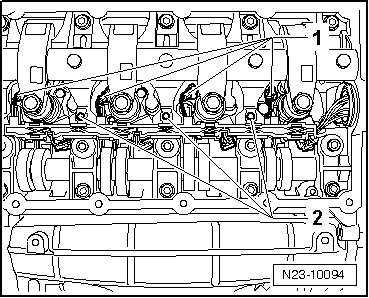

| Screw in press-off screws evenly in the order -1...4-, which is type-punched on the screw heads, until the bearing frame is being released from the cylinder head. |

Note | t

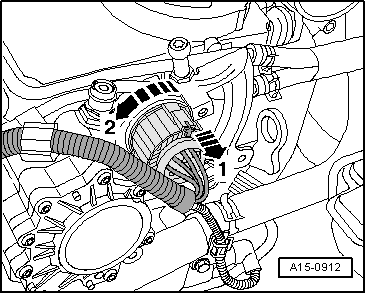

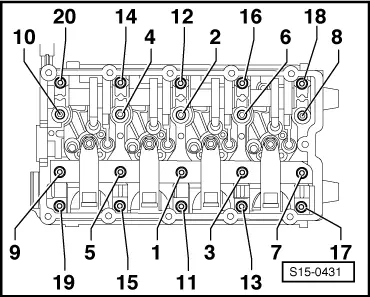

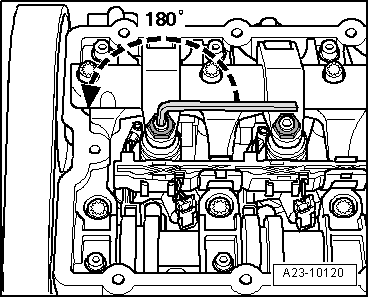

| Ensure that the bearing shells of the camshafts are not mixed up. |

| t

| Mark assignment of the bearing shells for the camshafts with waterproof marker on the reverse side. |

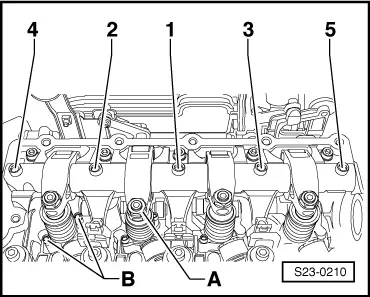

| Installation occurs in reverse order to removal. Pay attention to the following: |

WARNING | Wear protective gloves when working with sealant and grease remover! |

|

| –

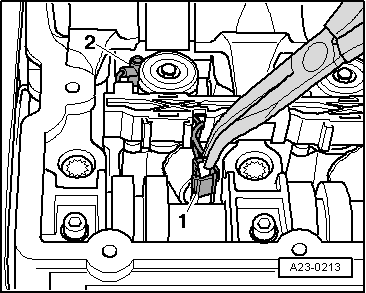

| Remove residual sealant on the bearing frame and cylinder head using a chemical sealant remover. |

| –

| Clean sealing surfaces, they must be free of oil and grease. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING