| Installing and adjusting the clutch |

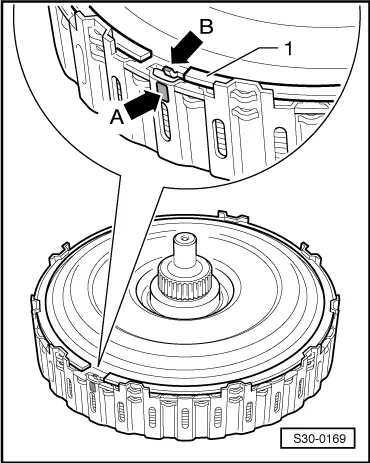

Caution | Try to avoid removing or raising the plate support. Not even a little bit! The plates can turn. |

|

Note | t

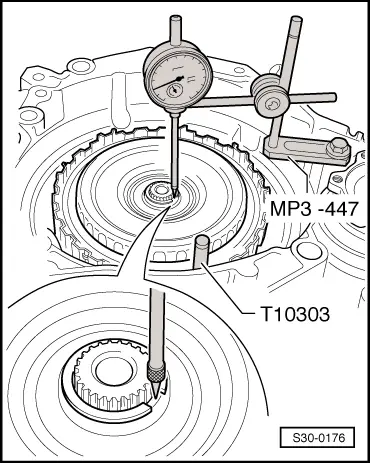

| The gearbox must be turned vertically in the assembly stand and the opening for the clutch must point upwards. Only in this way is it possible later on for the setting of the axial play of the clutch to be error-free. |

| t

| It is important that the gearbox is clamped firmly in the assembly stand -MP9-101- → Chapter, it must not be turned. |

| t

| In the clutch the large plate support must be inserted in all plates, it must not have slipped out of the lowest plate. |

| t

| The drive shaft of the gearbox oil pump is removed. |

| t

| Do not install corrugated circlips. |

| Special tools and workshop equipment required |

| t

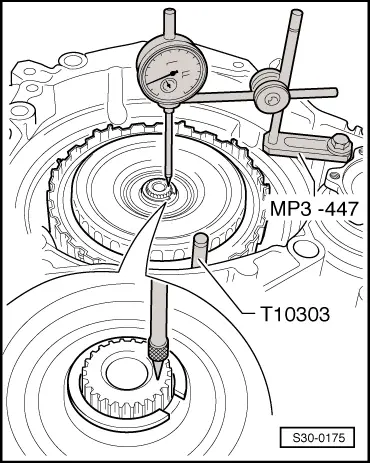

| Universal dial gauge holder -MP3-447 (VW 387)- |

| t

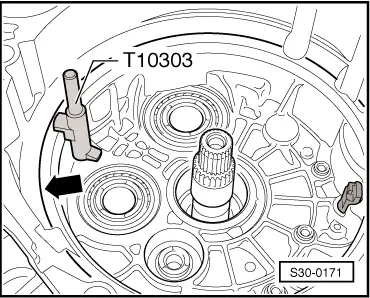

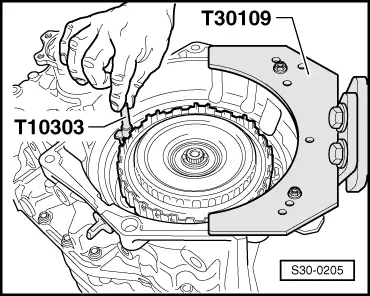

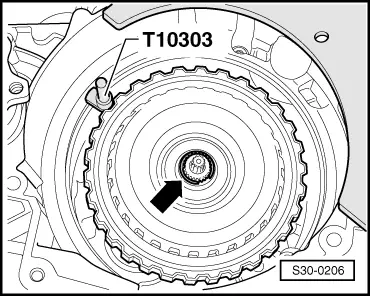

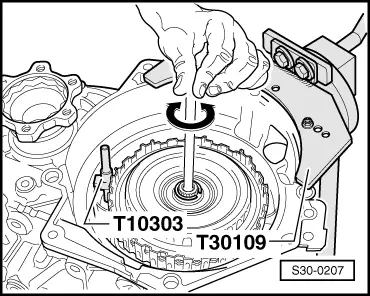

| Retaining bolt -T10303- |

| t

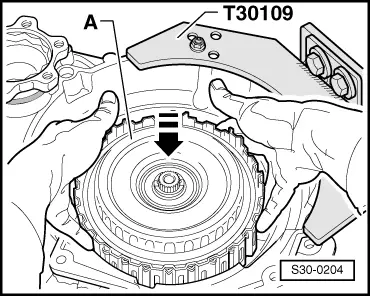

| Gearbox mount -T30109 (VW 353)- |

| t

| Assembly stand -MP9-101- |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution