| Removing gearbox, four-wheel drive (Octavia II) |

Note | t

| Observe instructions for automatic gearbox DSG - 02E → Chapter. |

| t

| Regulations concerning cleanliness when working on the gearbox → Chapter. |

| t

| All cable straps which are detached or cut open when removing, should be fitted on again in the same place when installing. |

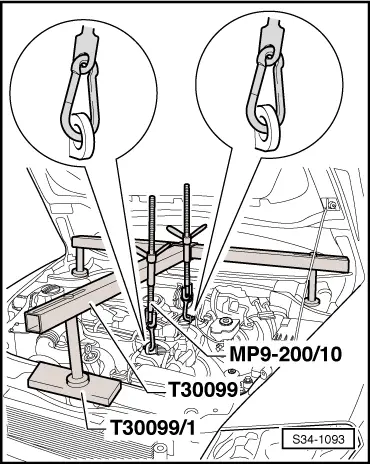

| Special tools and workshop equipment required |

| t

| Supporting device -T30099- |

| t

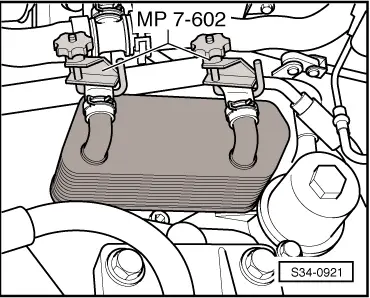

| Hose clamp -MP7-602 (3094)- |

| t

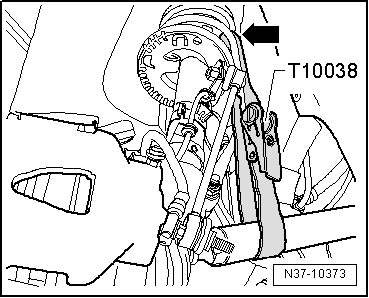

| Tensioning strap -T10038- |

| t

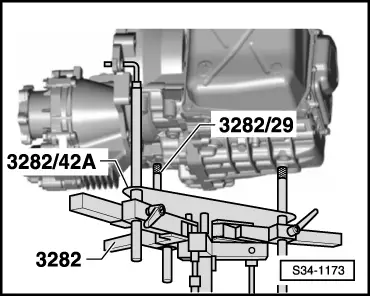

| Adjusting plate -3282/42A- |

| t

| Engine/gearbox jack, e.g. -V.A.G 1383 A- |

| t

| Pliers for spring strap clips, e.g. -VAS 6340- |

| t

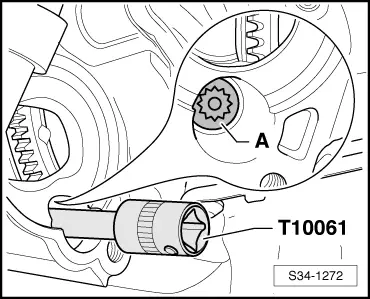

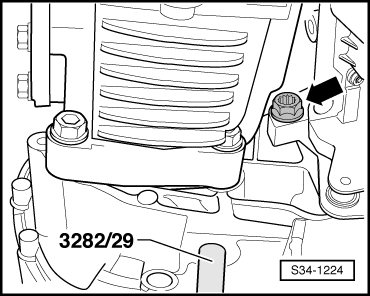

| Socket insert, e.g. -T10035- or socket insert XZN 14 -T10061- |

| t

| High-temperature grease -G 052 133 A2- |

| –

| Shift selector lever into position „P“. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING