| –

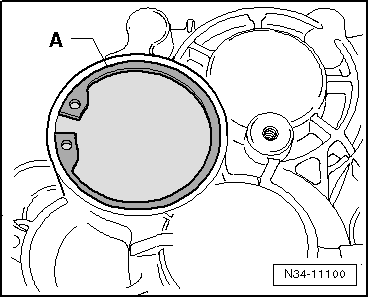

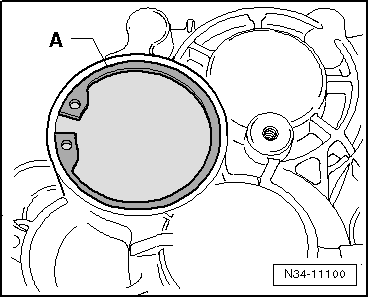

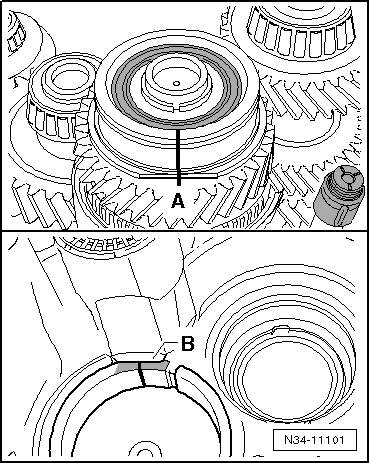

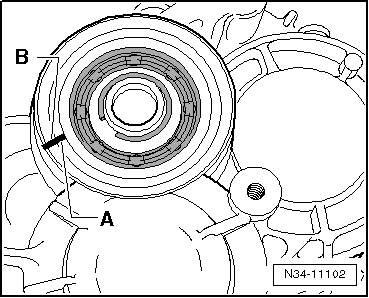

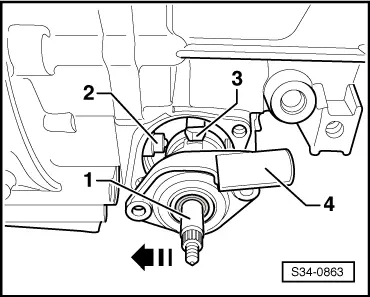

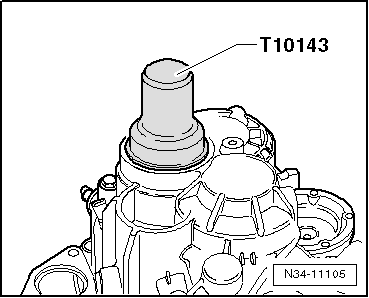

| Secure cap with circlip -A-. |

| –

| Remove gearbox from assembly stand. |

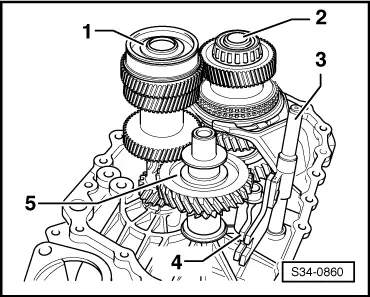

| Install angle gearbox as follows at the manual gearbox: |

| –

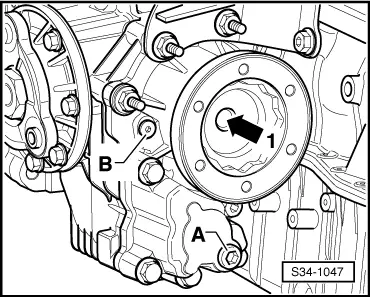

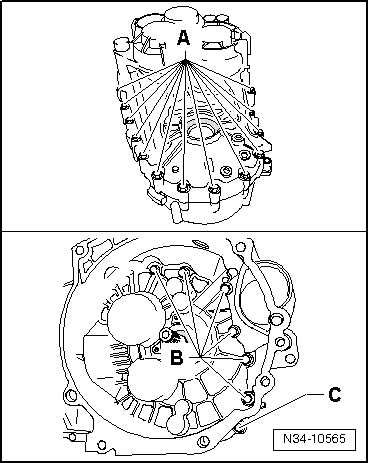

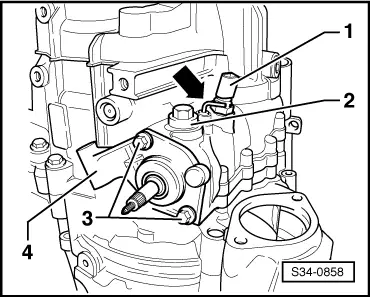

| On manual gearbox, lightly grease the rigid serration at differential gear with grease for the plug serration of the clutch disc - G 000 100-. |

| –

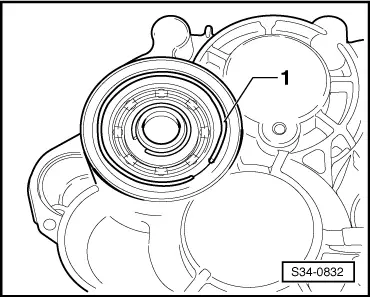

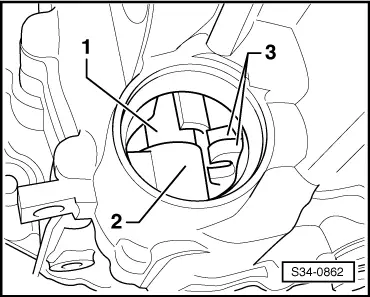

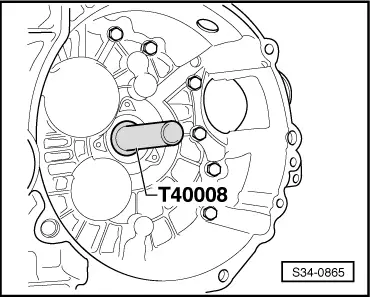

| Push angle gearbox fully onto the manual gearbox, while doing so slowly turn the flange shaft (carefully press angle gearbox onto gearbox up to stop). |

Note | t

| Do not pull angle gearbox with the fixing screws against the manual gearbox, otherwise the angle gearbox can tilt and the fixing eyes can break off. |

| –

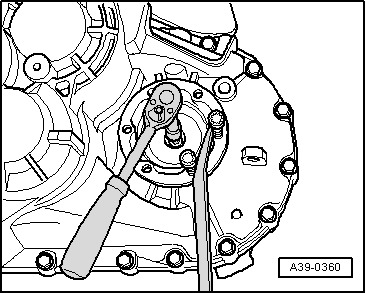

| Attach angle gearbox to gearbox and tighten connecting screws crosswise to tightening torque → Chapter Pos. 17. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note