Octavia Mk2

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

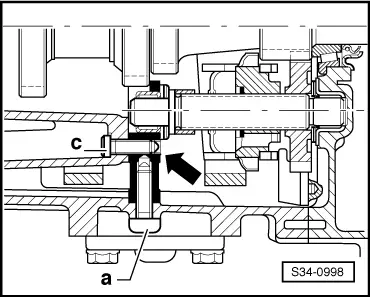

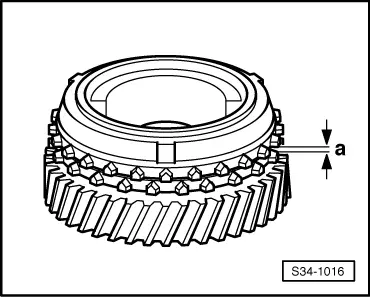

| Clearance -a- | Fitting dimension | Wear limit |

| 5th/ 6th gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

WARNING

WARNING