Octavia Mk2

|

|

|

|

|

|

|

|

|

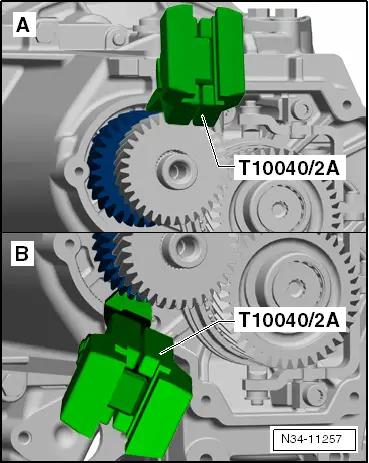

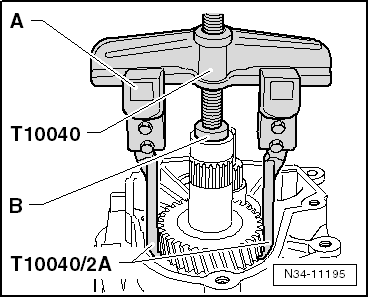

| The extraction hooks -T10040/2A- cannot be correctly positioned. | |||||||

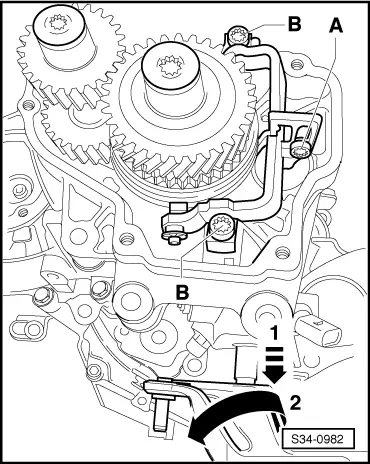

| -A- the extraction hooks -T10040/2A- come prematurely in contact with:

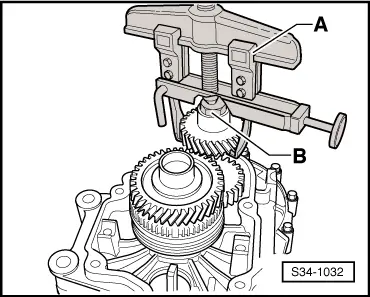

| Remove „together“: „5th/6th gear synchronizer body“, „6th gear pinion“, „5th gear pinion“ and „gearbox housing“ → Chapter | ||||||

| -B- the extraction hooks -T10040/2A- come in contact with the ribbing in the gearbox housing below the 5th gear pinion. | |||||||

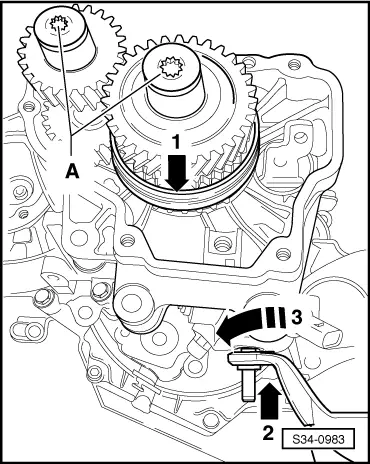

| The extraction hooks -T10040/2A- can be correctly positioned. | |||

| The 5th/6th gear can be removed separately → Anchor. |

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|