Octavia Mk2

|

|

|

|

|

|

|

|

|

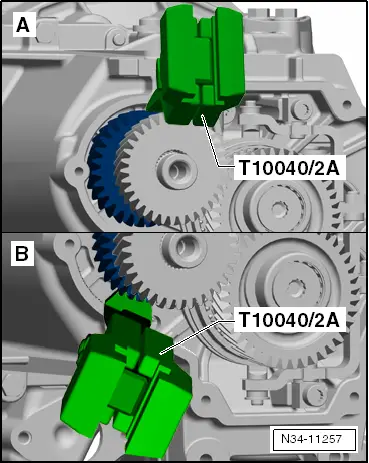

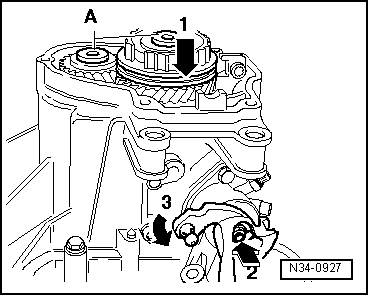

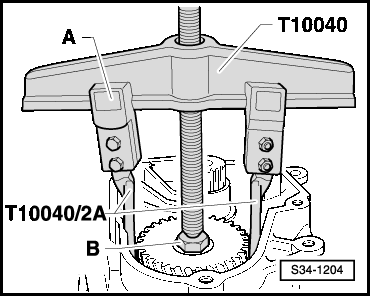

| The extraction hooks -T10040/2A- cannot be correctly positioned. | |||||||

| -A- the extraction hooks -T10040/2A- come prematurely in contact with:

| Remove „together“: „5th gear synchronizer body“, „5th gear pinion“ and „gearbox housing“ → Chapter | ||||||

| -B- the extraction hooks -T10040/2A- come in contact with the ribbing in the gearbox housing below the 5th gear pinion. | |||||||

| The extraction hooks -T10040/2A- can be correctly positioned. | |||

| 5th gear can be removed separately → Anchor. |

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|