Octavia Mk2

Note

Note| The gearshift fork group (Pos. 1) does not have to be disassembled for the disassembly and assembly of the shift segments, clamping plates and angular ball bearings. |

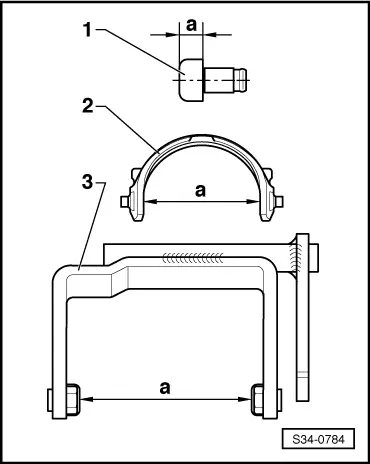

| 1 - | Gearshift fork group with shift rails |

| 2 - | 3rd/4th gear shift segment |

| q | Identification → Fig. |

| q | It must still be possible to rotate the shift segment freely once fitted |

| 3 - | Angular ball bearing |

| q | 4 pieces |

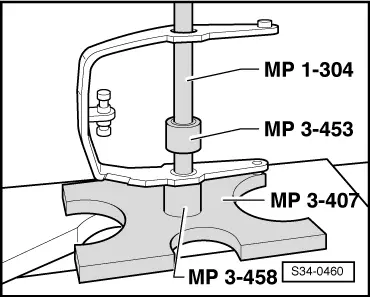

| q | pressing off → Fig. |

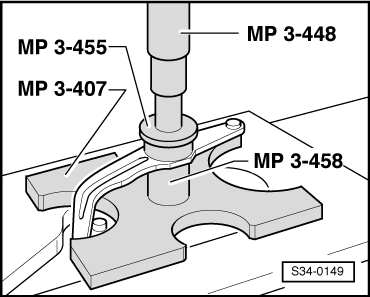

| q | installing → Fig. |

| 4 - | Circlip |

| q | always replace → Electronic Catalogue of Original Parts |

| q | removing → Fig. |

| q | installing → Fig. |

| 5 - | 1st/2nd gear shift segment |

| q | Identification → Fig. |

| q | It must still be possible to rotate the shift segment freely once the circlip has been fitted |

| q | Gearshift fork with shift segment |

| 6 - | 5th gear shift fork with shift segments |

| q | Shift segments are connected inseparably with the gearshift fork |

| q | Identification → Fig. |

| 7 - | Bearing bolt |

| q | for 5th gear shift fork |

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|