Octavia Mk2

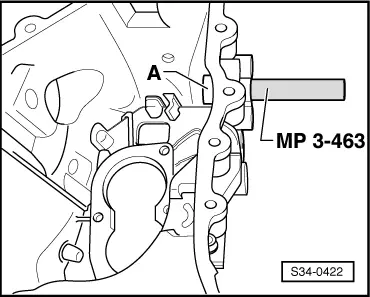

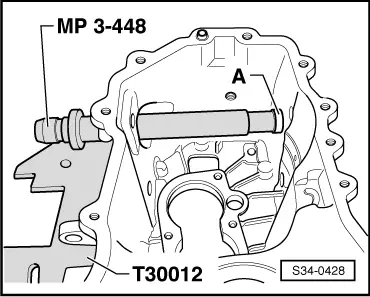

| 1 - | Bushing |

| q | for gearshift shaft |

| q | extracting → Fig. |

| q | inserting → Fig. |

| 2 - | Fitting sleeve |

| 3 - | Magnet |

| q | is held in position by the separator surface of the housing |

| 4 - | Screw cap |

| q | Before screwing down cover sealing surface with sealant -AMV 188 200- |

| 5 - | Circlip |

| q | inserted in the cylinder roller bearing groove |

| 6 - | Circlip |

| q | inserted in the cylinder roller bearing groove |

| 7 - | Cylindrical-roller bearing |

| q | for drive shaft |

| q | extracting and inserting → Chapter |

| 8 - | Cylindrical-roller bearing |

| q | for output shaft |

| q | extracting and inserting → Chapter |

| 9 - | Clutch housing |

| q | when replacing: Set the differential gear → Chapter |

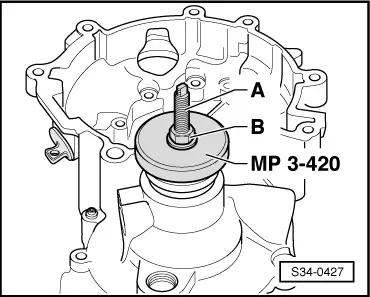

| 10 - | Gasket ring for drive shaft |

| q | release with a screwdriver |

| q | inserting → Fig. |

| 11 - | Ball stud - 20 Nm |

| q | grease with Grease -G 000 100- |

| 12 - | Seal ring for right flange shaft |

| q | release with a screwdriver |

| q | installing → Chapter |

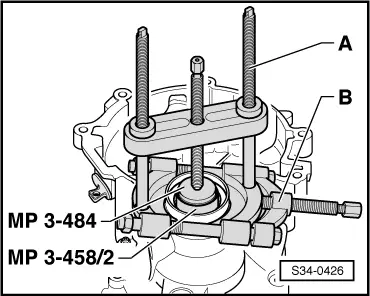

| 13 - | Bushing |

| q | for gasket ring |

| q | removing → Fig. |

| q | installing → Fig. |

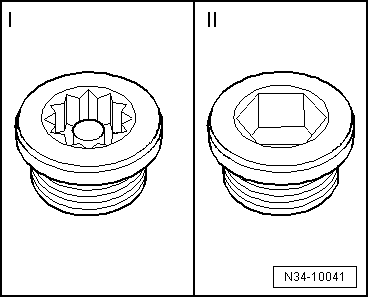

| 14 - | Oil filler plug |

| q | different versions: → Fig. |

| Oil filler plug or oil drain plug with internal serration - 24 Nm |

| Oil filler plug or oil drain plug with hexagon socket head - 32 Nm |

| 15 - | Adjusting washer S2 |

| q | for differential gear |

| q | Determine thickness → Chapter |

| 16 - | Outer ring/tapered-roller bearing |

| q | for differential gear |

| q | removing and installing → Chapter |

| q | when replacing, set the differential gear → Chapter |

| 17 - | 5 Nm and torque a further 90° |

| q | always replace → Electronic Catalogue of Original Parts |

| 18 - | Outer ring/tapered-roller bearing |

| q | for differential gear |

| q | removing and installing → Chapter |

| q | when replacing, set the differential gear → Chapter |

| 19 - | Adjusting washer S1 |

| q | for differential gear |

| q | always 1 mm thick |

| q | on gearboxes as of production date 12.06 the adjusting washer S1 for outer ring/tapered-roller bearing is not fitted → Chapter |

| q | Bearing pedestal for outer ring/tapered-roller bearing is adapted |

| 20 - | Fitting sleeve |

| 21 - | Gearbox housing |

| q | when replacing, set the differential gear → Chapter |

| q | on gearboxes as of production date 12.06 the adjusting washer S1 for outer ring/tapered-roller bearing is not fitted → Chapter |

| q | Bearing pedestal for outer ring/tapered-roller bearing is adapted |

| 22 - | Oil drain plug |

| q | different versions: → Fig. |

| Oil filler plug or oil drain plug with internal serration - 24 Nm |

| Oil filler plug or oil drain plug with hexagon socket head - 32 Nm |

| 23 - | Seal ring for left flange shaft |

| q | replace → Chapter |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|