Octavia Mk2

Note

Note

|

|

|

Note

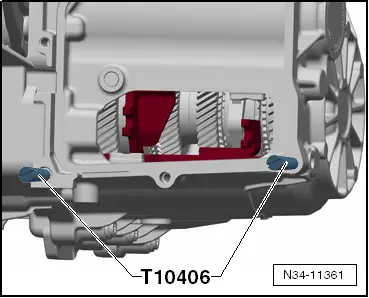

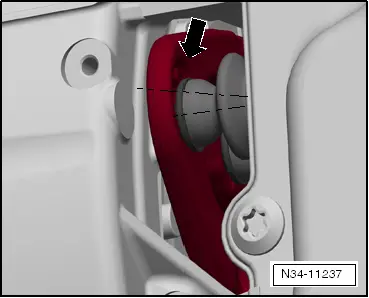

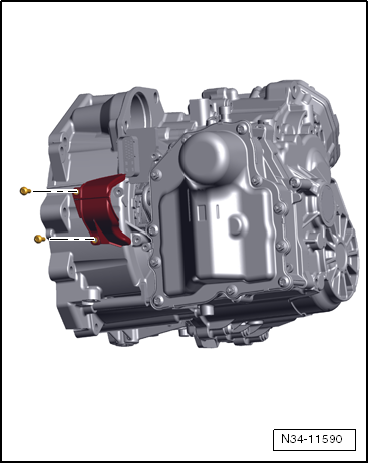

Note| t | Make sure that all the shift forks are in the »centre position« before installing the mechatronics for double clutch gearbox -J743-. |

| t | The »centre position« is shown in the illustration as position -N- (neutral). |

| t | No gear is engaged in this position, i.e neutral (neutral position) is engaged. |

| – | First check all 4 shift forks by hand. |

| All shift forks have 3 positions: |

| t | Gear engaged |

| t | Neutral -N- |

| t | Gear engaged |

| – | Consecutively bring all 4 shift forks once into each position -arrows-, if necessary turn a little on the pinions. |

| – | Then bring all the shift forks again into the »centre position«, position -N-. |

| N - | Neutral |

| R - | Reverse gear |

Note

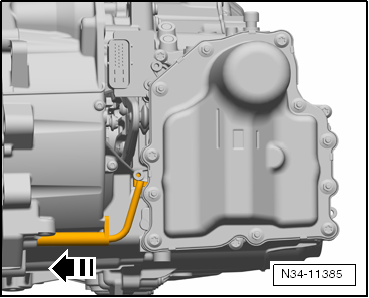

Note| t | When the reverse gear is engaged, the extended tappet of the mechatronics is hooked on the gearbox housing. |

| t | Therefore, the mechatronics must be put into the removal position by hand → Chapter. |

| 1 - | first gear |

| 2 - | second gear |

| 3 - | third gear |

| 4 - | fourth gear |

| 5 - | fifth gear |

| 6 - | sixth gear |

| 7 - | seventh gear |

|

|

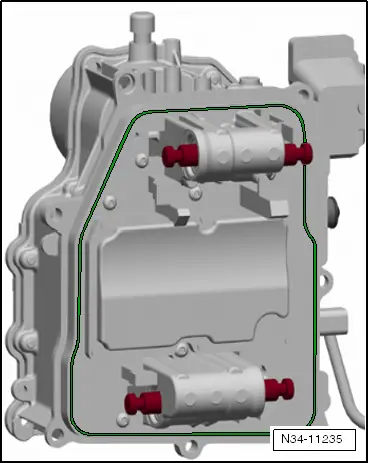

| Adjust gear actuator: |

Caution

Caution

|

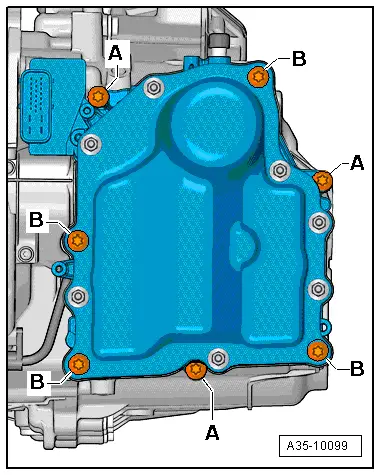

| – | Set the 4 gear switches on the rear side of the mechatronics for double clutch gearbox -J743- into the specified position. |

| Specified position: -a- = 25 mm |

Note

Note

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|