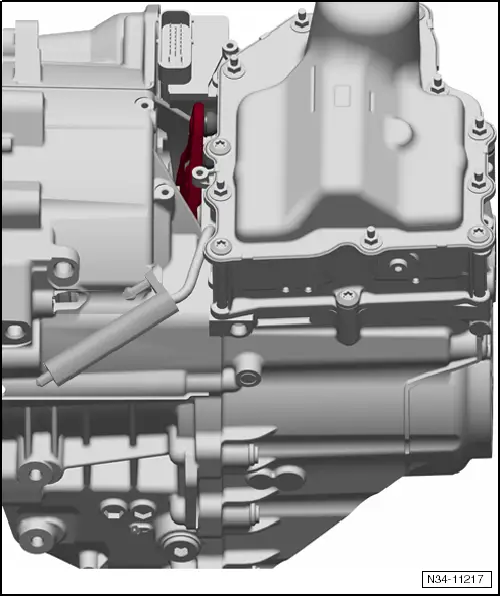

| Removing mechatronics for double clutch gearbox -J743-; gearbox installed (Octavia II, Superb II, Yeti) |

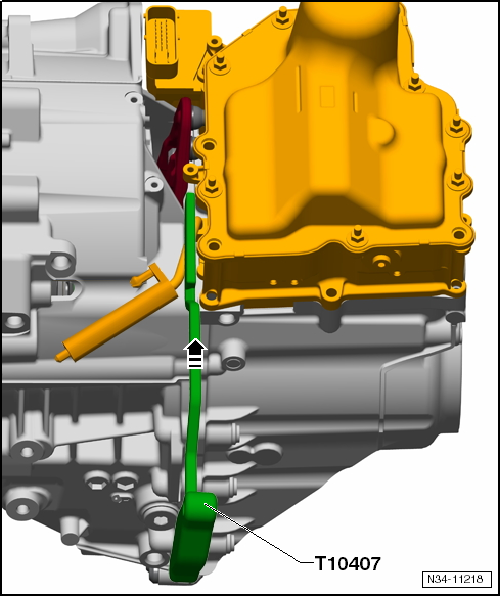

| Special tools and workshop equipment required |

| t

| Assembly lever -T10407- |

| t

| Vehicle diagnosis, measurement and information system -VAS- |

| t

| Catch pan for workshop crane -VAS 6208- |

Note | t

| Observe safety instruction for the mechatronics for double clutch gearbox -J743- → Chapter. |

| t

| Observe instructions for automatic gearbox DSG - 0AM → Chapter. |

| t

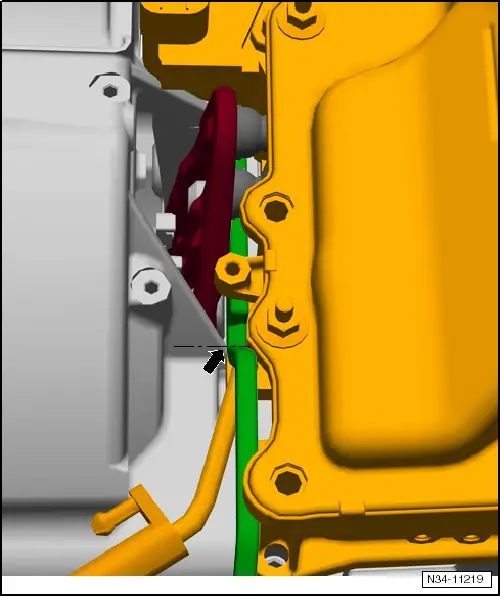

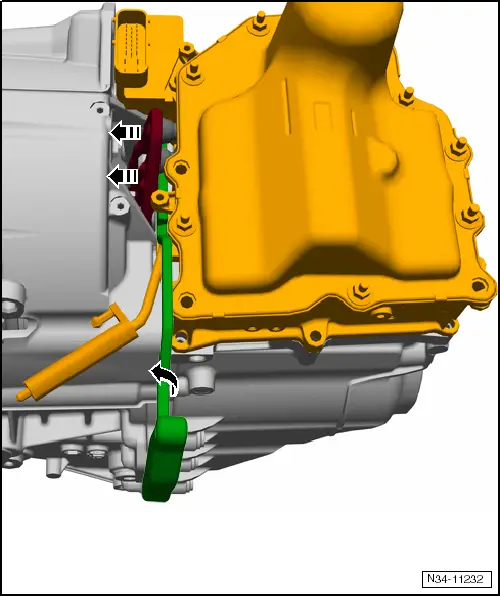

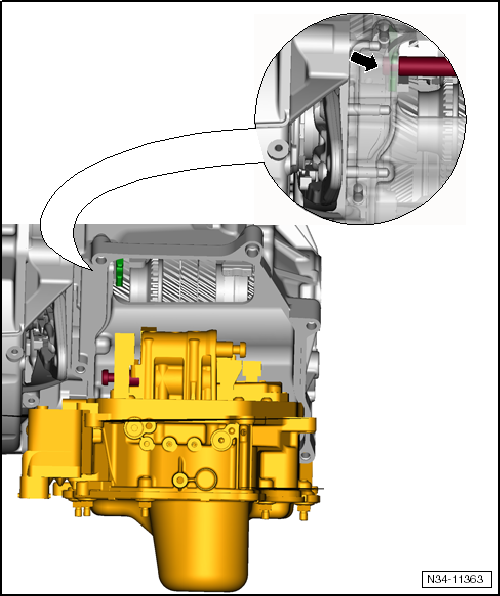

| The clutch is self-adjusting. Vibrations can have a negative effect on the adjusting device. Also when the mechatronics is removed, the »sudden removal« of the drifts below the engaging levers can have a negative effect on the adjusting device. |

| t

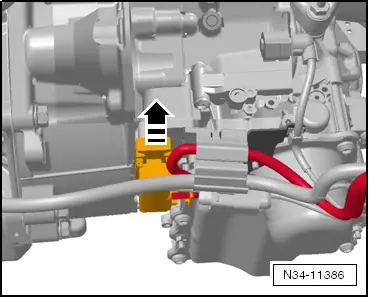

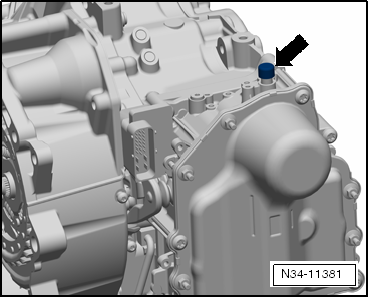

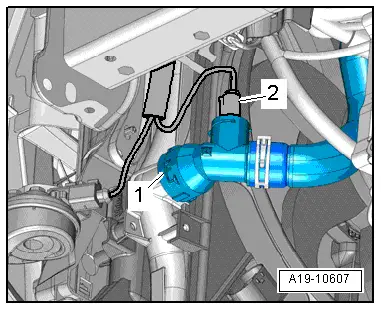

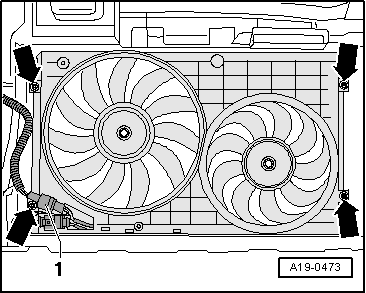

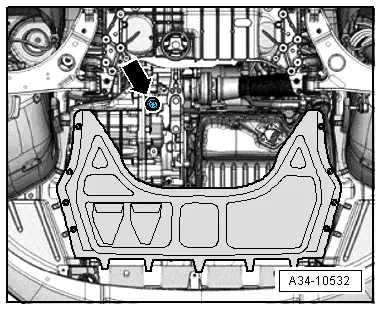

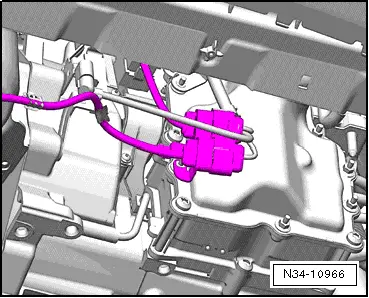

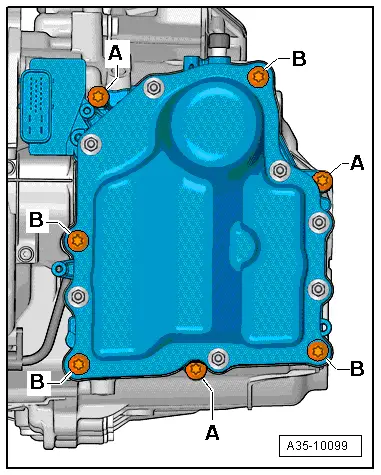

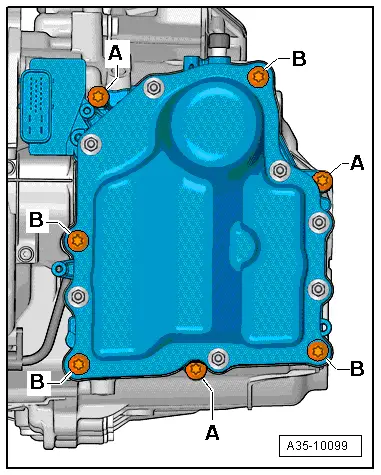

| Ensure adequate clearance in front of the gearbox in order to remove the mechatronics. Components, which are not directly connected with the gearbox, must be removed on some vehicles. The existing brackets, if applicable, must be removed at the screws of the cover for mechatronics. |

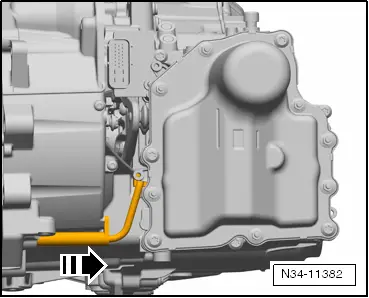

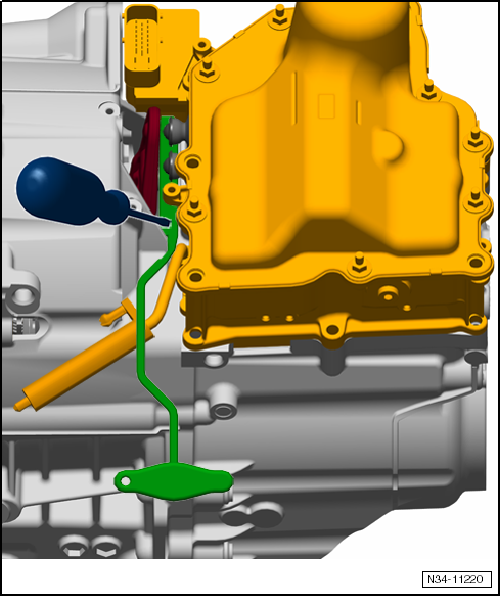

| The mechatronics remains filled with oil |

| –

| Shift selector lever into position »P«. |

| Before the actual removal of the mechatronics, carry out the basic setting of the »idle position« of the gearbox with the → Vehicle diagnostic tester. |

| –

| Select Targeted functions and subsequently select the basic setting of the idle position. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING Caution

Caution