Octavia Mk2

Note

Note| t | Before installing heat the inner ring of the tapered-roller bearing to 100°C. |

| t | Replace both tapered-roller bearings together. |

| t | When replacing the tapered-roller bearings, the differential housing, the gearbox housing or the clutch housing, set the differential gear → Chapter. |

| 1 - | Conical screw, 25 Nm |

| q | screw into threaded piece Pos. 8 |

| 2 - | Right flange shaft |

| 3 - | Pressure spring for flange shaft |

| q | fitted behind flange shaft |

| 4 - | Thrust washer |

| q | Fitting position: Collar towards pressure spring |

| 5 - | Conical ring |

| q | Fitting position: Cone towards differential gear housing |

| 6 - | Circlip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

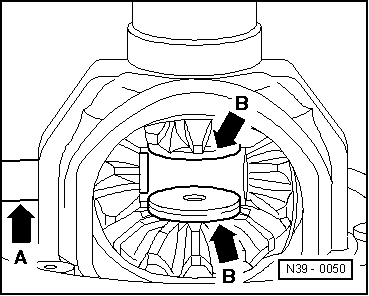

| 7 - | Large differential bevel gear |

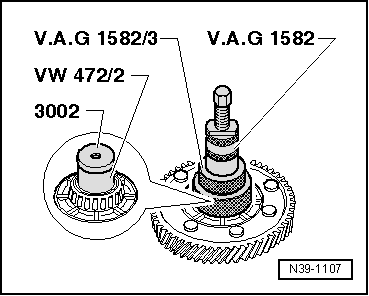

| q | installing → Fig. |

| 8 - | Threaded part |

| q | installing → Fig. |

| 9 - | Differential bevel gear shaft |

| q | to remove cut tensioning sleeve Pos. 17 → Fig. |

| q | installing → Fig. |

| 10 - | Small differential bevel gear |

| q | installing → Fig. |

| 11 - | Stop disc compound |

| q | insert with gear oil |

| 12 - | Flange shaft left |

| 13 - | Sealing ring |

| q | for left flange shaft |

| q | replace with installed gearbox → Chapter |

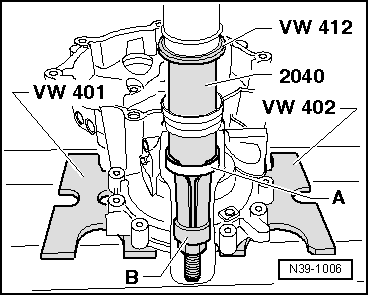

| 14 - | Outer ring/tapered-roller bearing |

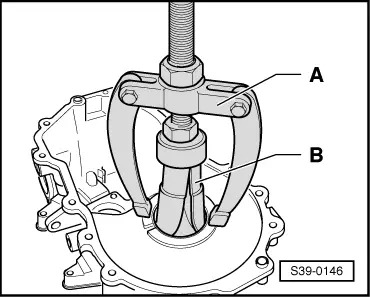

| q | removing → Fig. |

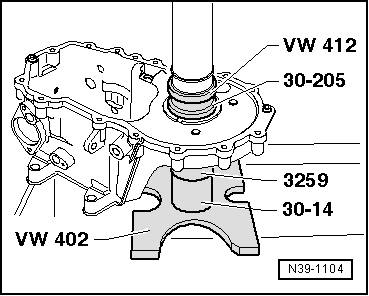

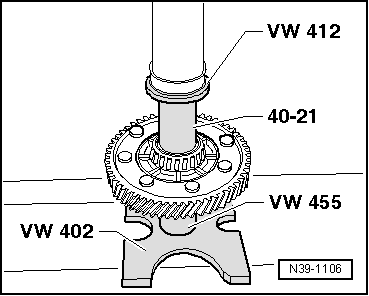

| q | installing → Fig. |

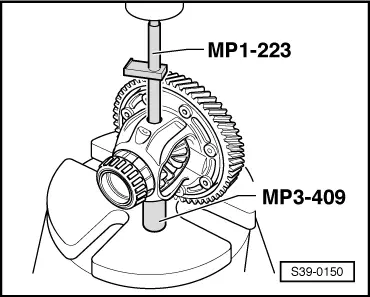

| 15 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 16 - | Differential gear housing |

| q | with gear pinion for final drive |

| 17 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

| q | is cut when removing → Fig. |

| q | installing → Fig. |

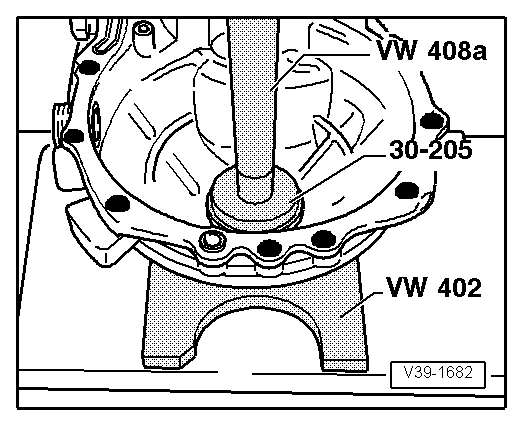

| 18 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 19 - | Outer ring/tapered-roller bearing |

| q | pressing out → Fig. |

| q | pressing on → Fig. |

| 20 - | Adjusting washer |

| q | for the differential gear |

| q | Determine thickness → Chapter |

| 21 - | Sealing ring |

| q | for right flange shaft |

| q | replace with installed gearbox → Chapter |

| 22 - | Clutch housing |

| 23 - | Gearbox housing |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|