Octavia Mk2

Note

Note| t | When installing new pinions or a new output shaft observe the technical data → Chapter. |

| t | Insert all bearings, sliding gears and synchronizer rings onto the output shaft with gear oil. |

| t | Do not interchange the synchronizer rings, if re-used always assign to the original sliding gear. |

| 1 - | Clutch housing |

| q | repairing → Chapter |

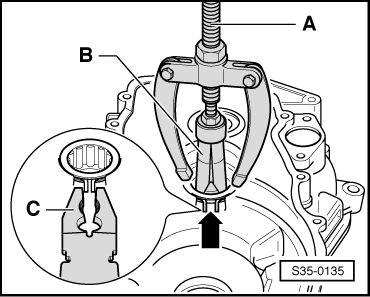

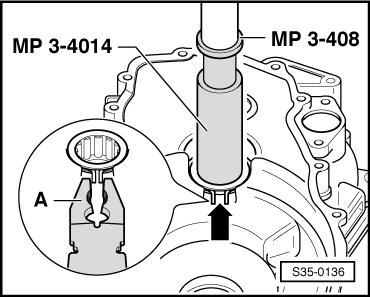

| 2 - | Cylindrical-roller bearing |

| q | with circlip |

| q | removing → Fig. |

| q | installing → Fig. |

| q | Fitting position: the circlip in the bearing points towards the output shaft |

| 3 - | Output shaft |

| q | if an inner ring is fitted as a bearing assembly for the cylindrical-roller bearing Pos. 2, it cannot be removed from the output shaft |

| q | Inspect bearing assembly or inner ring for cylindrical-roller bearing for scoring and damage |

| q | Replace output shaft and cylindrical-roller bearing together if there is scoring or damage on the bearing assembly or inner ring |

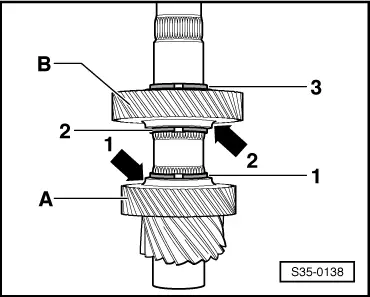

| 4 - | 4th gear pinion |

| q | Fitting position: the collar points to the 3rd gear → Fig. |

| q | No. of teeth → Chapter |

| 5 - | Circlip |

| 6 - | Circlip |

| 7 - | 3rd gear pinion |

| q | Fitting position: the collar points to the 4th gear → Fig. |

| q | No. of teeth → Chapter |

| 8 - | Circlip |

| 9 - | 2nd gear sliding gear |

| q | No. of teeth → Chapter |

| 10 - | Needle bearing |

| q | for 2nd gear |

| 11 - | Inner ring for 2nd gear |

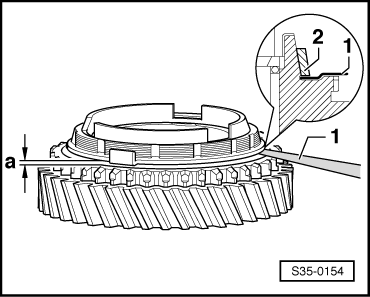

| q | check for wear → Fig. |

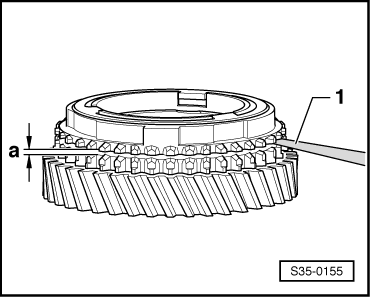

| q | Fitting position → Fig. |

| 12 - | Outer ring for 2nd gear |

| q | place onto the inner ring Pos. 11 |

| q | replace if there are any traces of scoring or friction |

| q | Fitting position → Fig. |

| 13 - | 2nd gear synchronizer ring |

| q | check for wear → Fig. |

| q | Fitting position → Fig. |

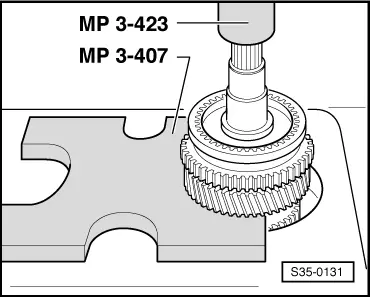

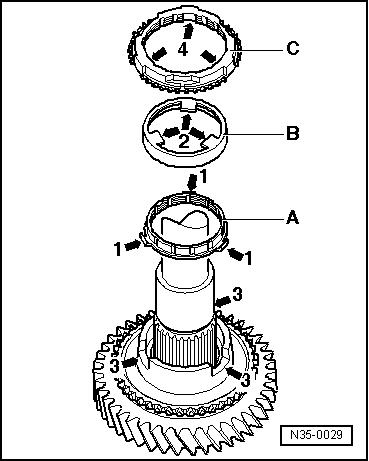

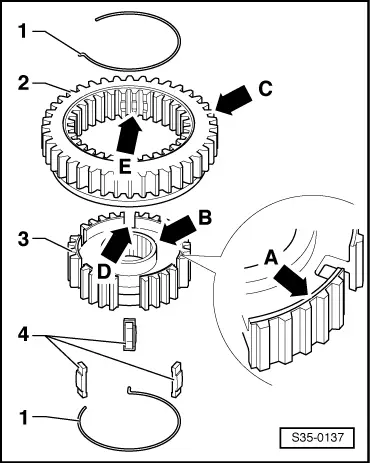

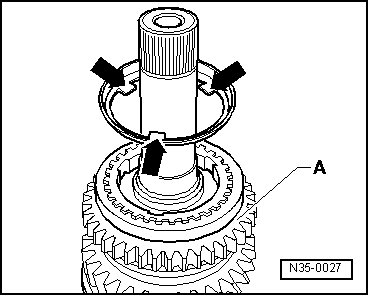

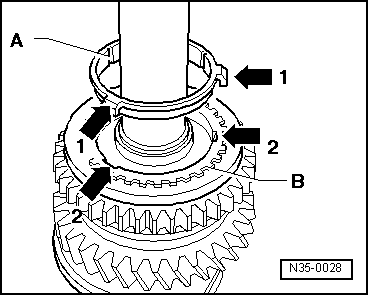

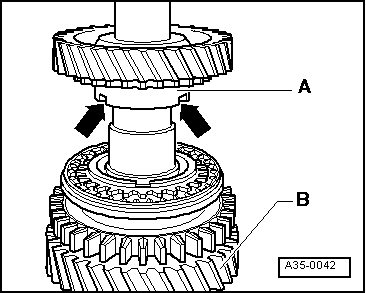

| 14 - | Sliding sleeve with 1st and 2nd gear synchronizer body |

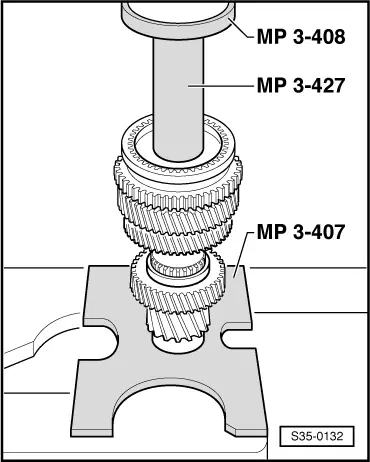

| q | after removing the circlip -Pos. 15- press off with the 2nd gear sliding gear → Fig. |

| q | disassembling → Fig. |

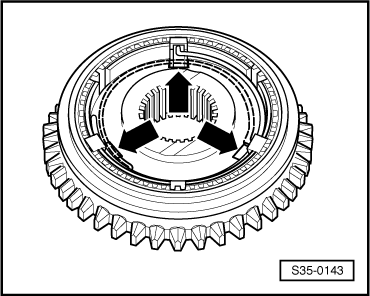

| q | Assembling sliding sleeve/synchronizer body → Fig. and → Fig. |

| q | Fitting position → Fig. |

| q | pressing on → Fig. |

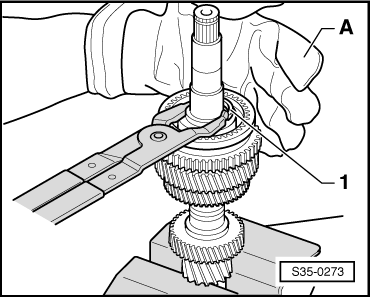

| 15 - | Circlip |

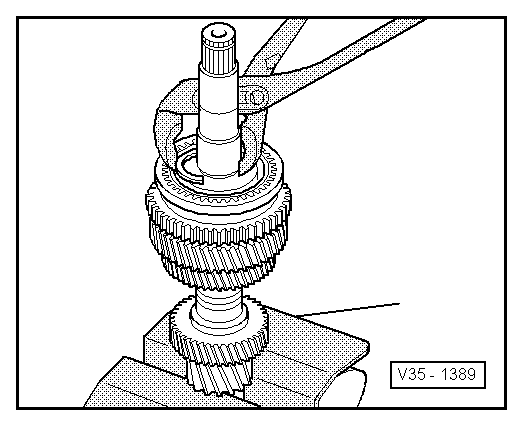

| q | pushing out → Fig. |

| q | inserting → Fig. |

| 16 - | 1st gear synchronizer ring |

| q | check for wear → Fig. |

| q | insert in such a way that the recesses lock into the arresters of the sliding sleeve Pos. 14 |

| 17 - | Outer ring for 1st gear |

| q | insert into synchronizer ring Pos. 16 |

| q | Fitting position → Fig. |

| q | replace if there are any traces of scoring or friction |

| 18 - | Inner ring for 1st gear |

| q | check for wear → Fig. |

| q | Check pegs for traces of wear |

| q | Fitting position → Fig. |

| 19 - | Needle bearing |

| q | for 1st gear |

| 20 - | 1st gear sliding gear |

| q | Fitting position → Fig. |

| q | No. of teeth → Chapter |

| 21 - | Bearing support with grooved ball bearing |

| q | Always replace grooved ball bearing together with the bearing support |

| q | If the bearing support is released from the gearbox housing, it must always be replaced → Electronic Catalogue of Original Parts |

| q | removing and installing → Chapter |

| 22 - | Gearbox housing |

| q | repairing → Chapter |

| 23 - | Screw |

| q | removing and installing → Chapter |

| 24 - | Inner ring/cylindrical-roller bearing |

| q | identify before removing |

| q | do not interchange with inner ring/cylindrical-roller bearing of input shaft |

| q | can be replaced separately |

| q | removing and installing → Chapter |

| 25 - | 6th gear pinion |

| q | Fitting position: the collar points to the bushing Pos. 26 |

| q | removing and installing → Chapter |

| q | No. of teeth → Chapter |

| 26 - | Bushing |

| q | removing and installing → Chapter |

| 27 - | 5th gear pinion |

| q | Fitting position → Chapter |

| q | press off together with bearing support Pos. 21 → Chapter |

| q | pressing on → Chapter |

| q | No. of teeth → Chapter |

| 28 - | Spring |

| q | Fitting position → Fig. |

| 29 - | Sliding sleeve |

| 30 - | Synchronizer body |

| 31 - | Arresters (3 pieces) |

|

|

|

|

|

|

|

|

|

|

|

|

| Fitting dimension | Wear limit | |

| Clearance -a- | 0,75 … 1,25 mm | 0.3 mm |

|

|

| Fitting dimension | Wear limit | |

| Clearance -a- | 1,2 … 1,8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING