| Special tools and workshop equipment required |

| t

| NAC milling cutter for reworking valve seats |

Note | t

| When carrying out repairs on engines with leaking valves, it is not sufficient to machine or replace the valve seats and valves. It is also necessary to inspect the valve guides for wear, particularly on engines with a high mileage → Chapter. |

| t

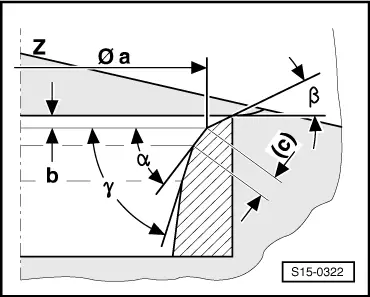

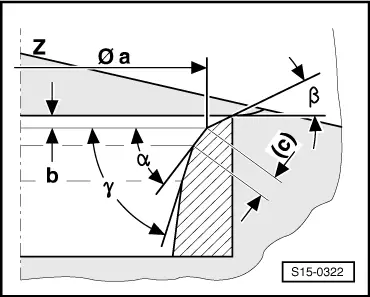

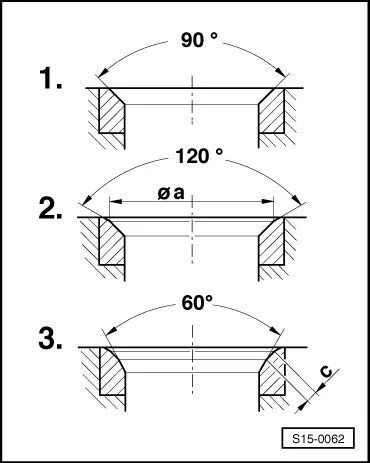

| Rework valve seats only sufficiently in order to obtain a proper contact pattern. Calculate the maximum permissible reworking dimension before commencing. If the reworking dimension is exceeded, the proper operation of the hydraulic valve clearance compensation is no longer ensured. If this is the case replace the cylinder head. |

| Calculating maximum permissible reworking dimension |

| –

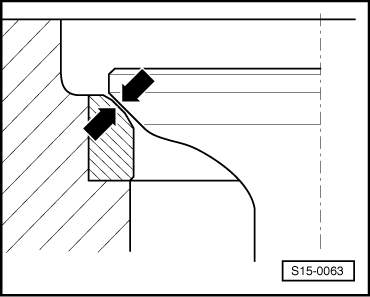

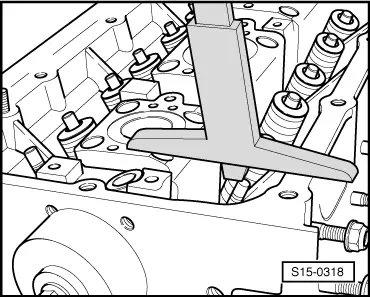

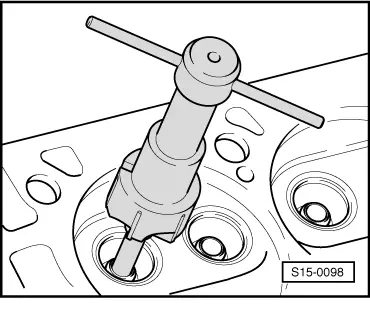

| Insert valve into the guide and press firmly against the valve seat. |

Note | If the valve is replaced when carrying out repair work, use a new valve for the measurement. |

|

|

|

Note

Note Note

Note

Note

Note