| –

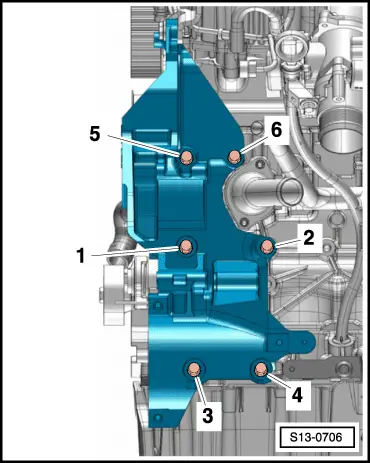

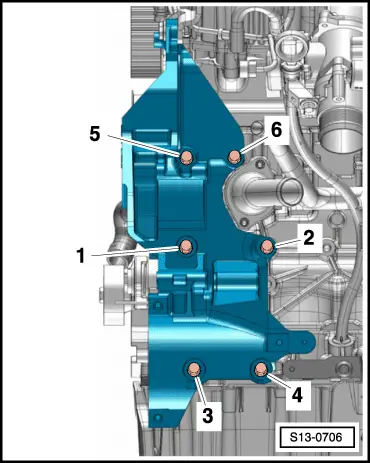

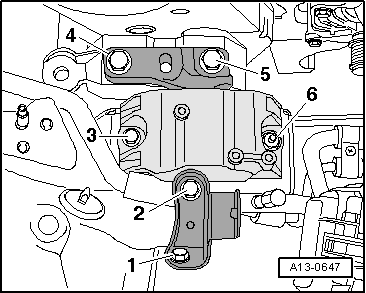

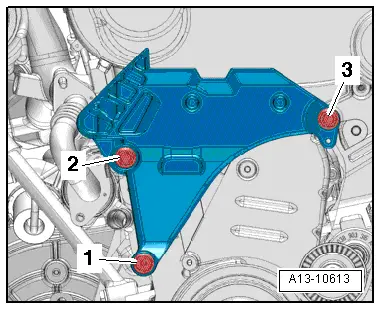

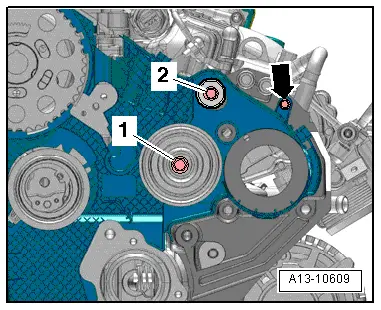

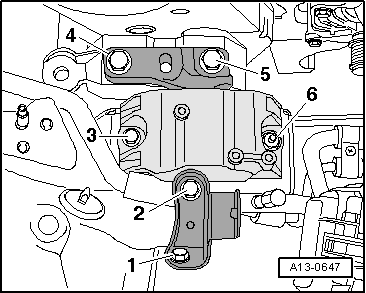

| Release screws -1 ... 6- and remove bracket for auxiliary units. |

| Installation is performed in the reverse order, pay attention to the following points: |

Note | Replace screws which have been tightened to a torquing angle. |

| –

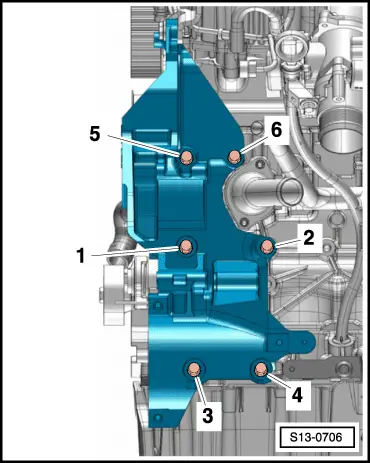

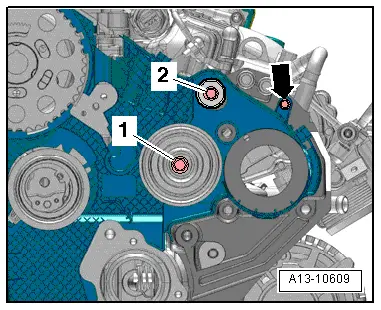

| If no dowel sleeves are present on the top right between the bracket for auxiliary units and the cylinder block, insert dowel sleeves. |

| –

| Tighten the screws for the bracket for auxiliary units. |

| t

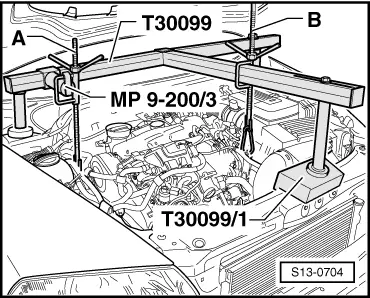

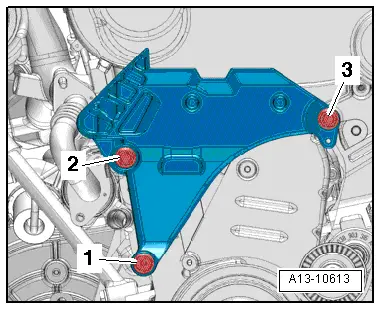

| On vehicles without air conditioning system → Fig.. |

| t

| On vehicles with air conditioning system → Fig.. |

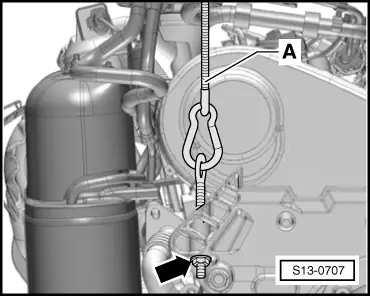

| On vehicles with air conditioning |

| –

| Install AC compressor at the bracket for auxiliary units → Chapter. |

| –

| Filling and bleeding the fuel system. For this purpose, connect the vehicle diagnosis, measurement and information system -VAS 505x- and carry out the targeted function „bleeding the fuel system“. During this function, the fuel pump is actuated for 180 seconds. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note