| –

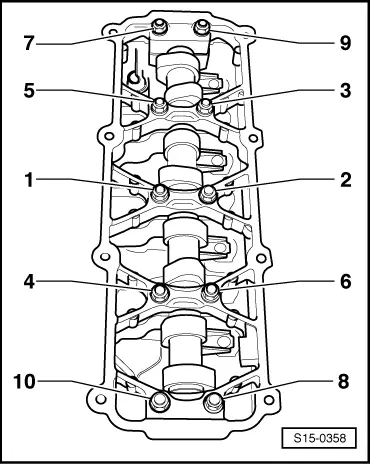

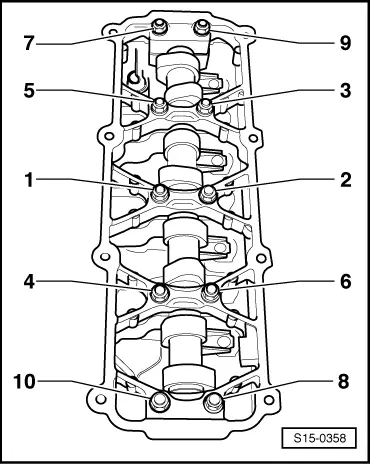

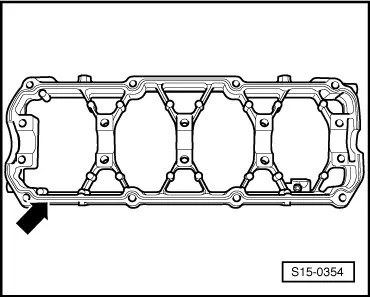

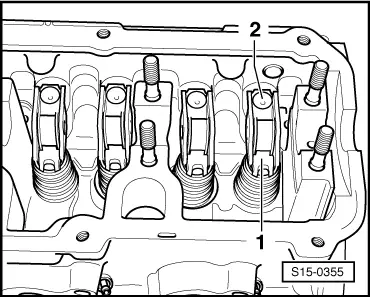

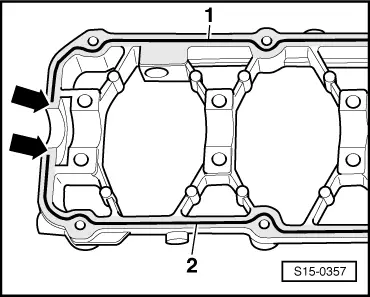

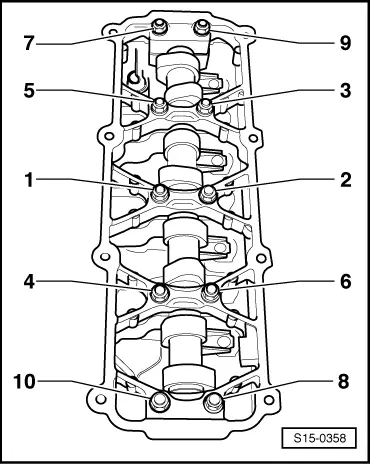

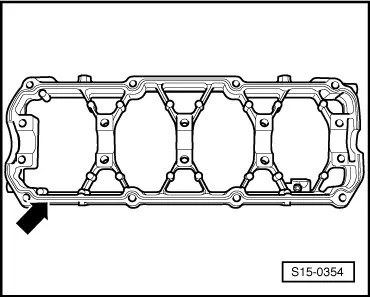

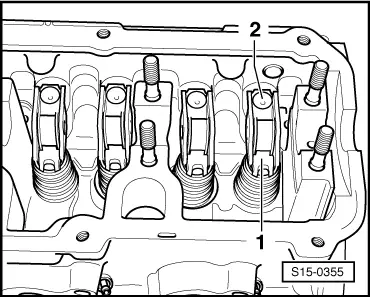

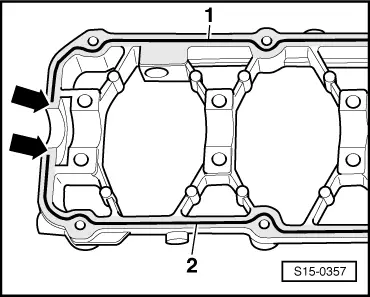

| Position ladder frame and slightly tighten the nuts -3-, -4-, -5-, -6- in several stages crosswise. |

| –

| Then, slightly tighten the nuts -1-, -2-, -7-, -8-, -9-, -10-. |

| –

| Then tighten the nuts in the sequence -1…10-. |

Note | t

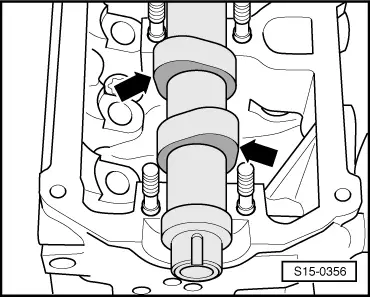

| After installing the ladder frame and the cylinder head cover, allow the sealant to dry for about 30 minutes. |

| t

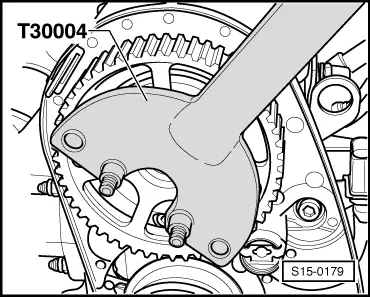

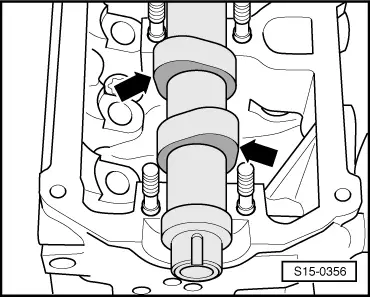

| After installing the camshaft, the engine must not be started for about 30 minutes. The hydraulic clearance compensation elements must settle (otherwise valves would strike the pistons). |

| t

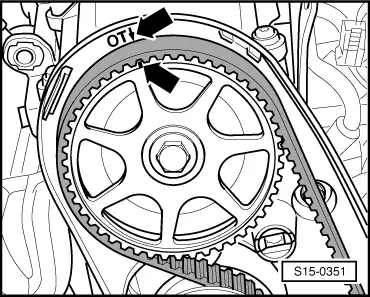

| After carrying out work on the valve gear, carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note