| Venting air from the fuel system |

Note | t

| In order to avoid damage to the catalyst, the fuel system without return-flow line must be bled after working on the fuel lines or at the fuel filter. The vehicle can only be started after bleeding. |

| t

| Observe safety measures and rules of cleanliness when working on the fuel supply → Chapter. |

| Special tools and workshop equipment required |

| t

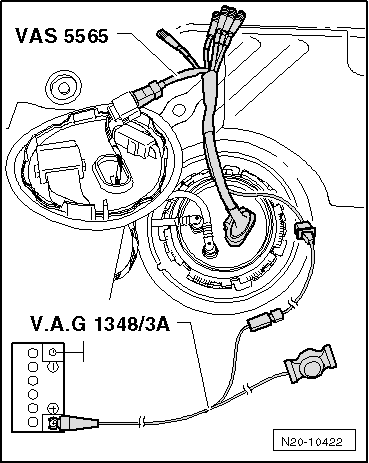

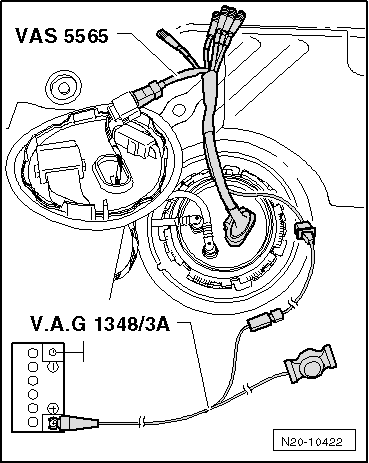

| Remote control -V.A.G 1348/3 A- |

| t

| Adapter for measuring method/DSO (5-pin), e.g. -VAS 5565- |

| t

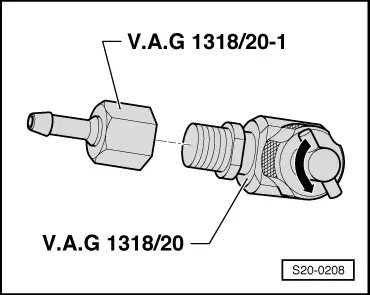

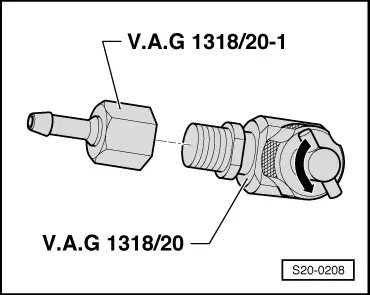

| Adapter -V.A.G 1318/20- |

| t

| Adapter -V.A.G 1318/20-1- |

| t

| Hose clamps 40 mm, e.g. -T30096 (3093)- |

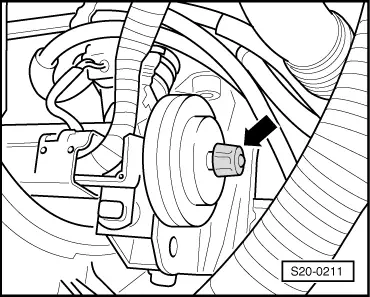

WARNING | The fuel system is under pressure! Before opening the system lay cleaning cloths around the connection point. Reduce pressure by carefully releasing the connection point. |

|

| –

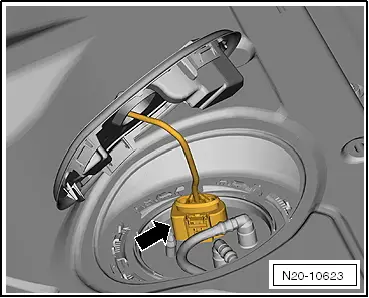

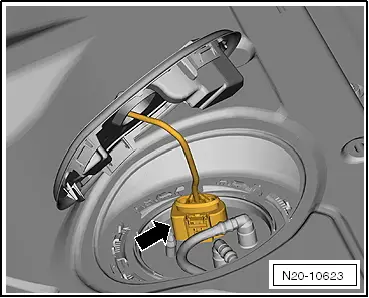

| Remove the cover from the fuel delivery unit. |

Note | For vehicles with auxiliary heating, the plug connection for the dosing pump -V54- must be disconnected additionally. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note