| –

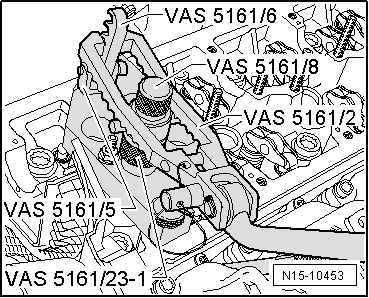

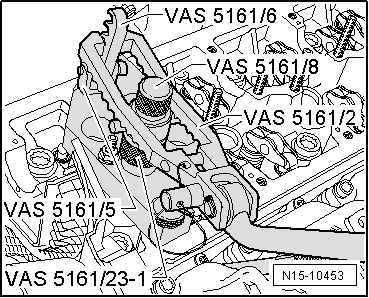

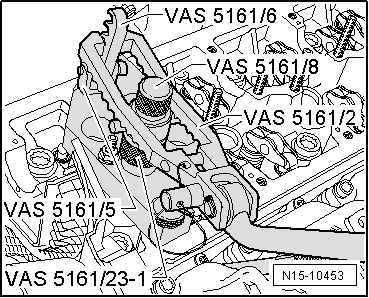

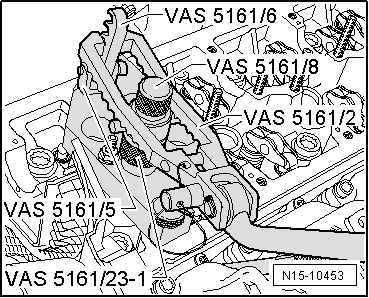

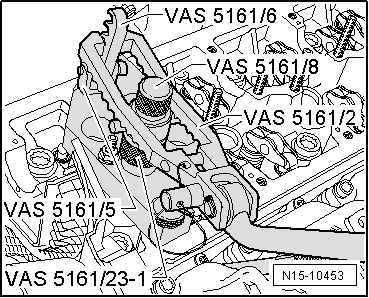

| Screw the detent part -VAS 5161/6- with the interlocking fork -VAS 5161/5- into the guide plate. |

| –

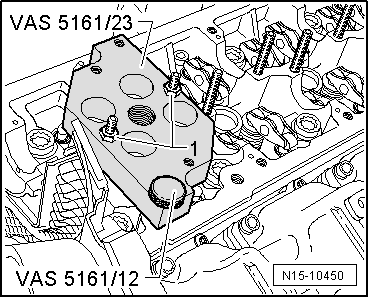

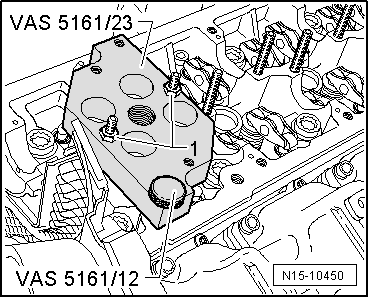

| Slide the knurled spacer ring -VAS 5161/23-1- onto the assembly cartridge -VAS 5161/8-. |

| –

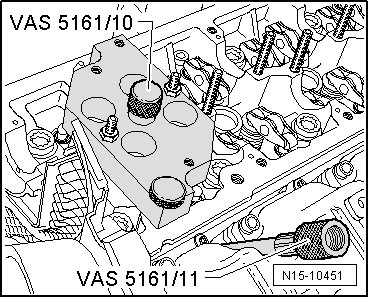

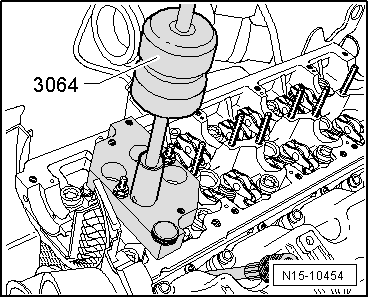

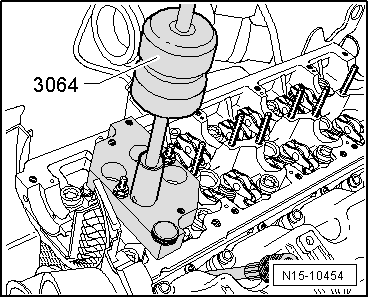

| Connect the adapter to the compressed air with a commercially available intermediate piece and apply constant pressure. |

| l

| Minimum pressure: 0.6 MPa (6 bar) overpressure. |

| –

| Hook the pressure fork -VAS 5161/2- onto the detent part and push the assembly cartridge downwards. |

| –

| Turn simultaneously the knurled screw of the assembly cartridge to the right, until the tips click into the valve collets. |

| –

| Rotate the knurled screw to the left and to the right, by doing so the valve collets are pressed apart and are installed in the assembly cartridge. |

| –

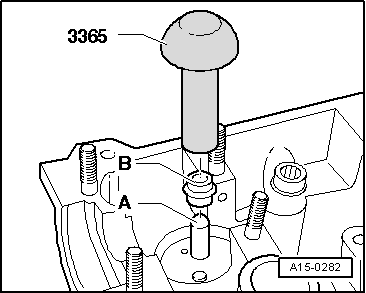

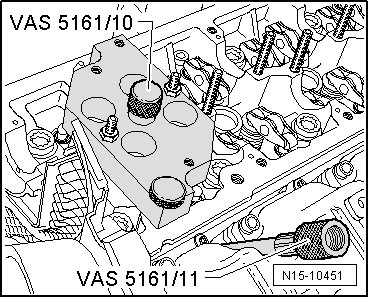

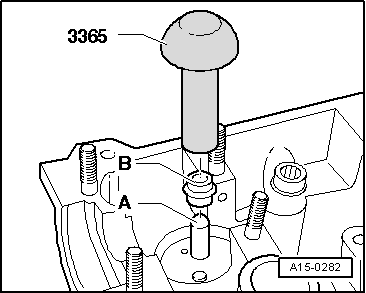

| Release the pressure fork. |

| –

| Remove the assembly cartridge with the knurled spacer ring. |

| –

| Remove the valve spring with the valve spring retainer. |

|

|

|

Note

Note

Note

Note