| Replacing and adjusting the vacuum setting element for exhaust turbocharger |

| Special tools and workshop equipment required |

| t

| 10 mm wrench socket -T10422- |

| t

| Ring spanner 10 x 12 -T10423- |

| t

| Socket wrench insert -T40055- |

| t

| Thin paint brush (approx. 20 cm long) |

| t

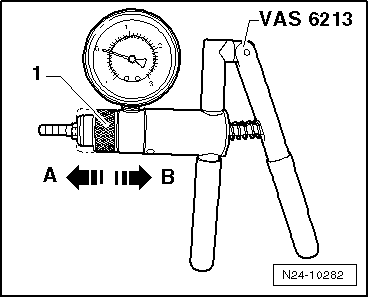

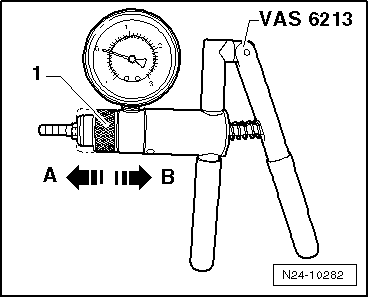

| Hand vacuum pump, e.g. -VAS 6213- |

Caution | The special tools listed, in particular the socket wrench -T10422-, must be used exclusively as described below and must not be used for any other screwed connections. Risk of deformations, opening and slipping of the wrench at higher tightening torques. |

|

Note |

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note