| Important instructions for installing the injection units: |

| When reinstalling the injection unit, the following parts must be replaced: |

| t

| O-ring for gasket of bore in cylinder head |

| t

| O-ring for fuel return-flow line |

| When installing the new injection unit (injectors), the following must also be replaced: |

| t

| High pressure line between fuel high pressure reservoir and injection unit (injection pipe) |

| Instructions for reinstalling the injection units |

Note | t

| When reinstalling, the injection units and the high pressure lines must only be installed on the same point from which they were removed. |

| t

| The reinstalled injection units (injectors) or high pressure lines must not be damaged. |

| t

| Check the injection units and the fitting positions for cleanliness before installing. |

| t

| All the O-rings must be coated with engine oil before installing. |

| If a used injection unit is reinstalled |

| –

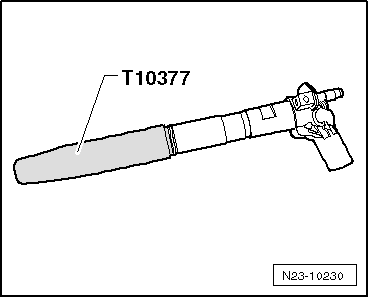

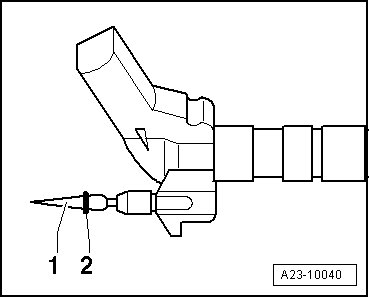

| Spray the tip of the injection unit with a rust solvent spray. Remove the soot and grease particles with a cloth after approx. 5 minutes. |

| –

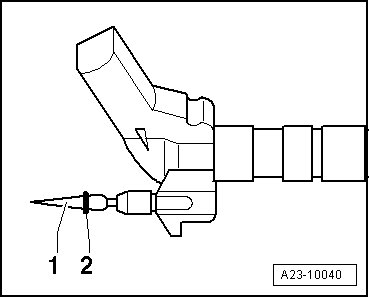

| Remove the old copper seal from the injection unit; to do so, carefully tighten the copper seal in a vice until the copper seal does no longer turn. Then pull the injection unit out of the copper seal with slight turning and pulling movements of the hand. |

| Continued for all injection units |

| –

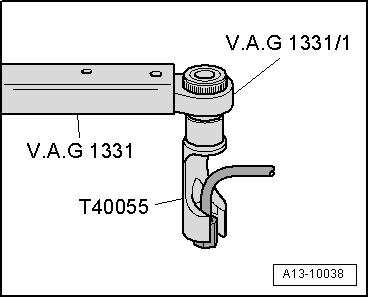

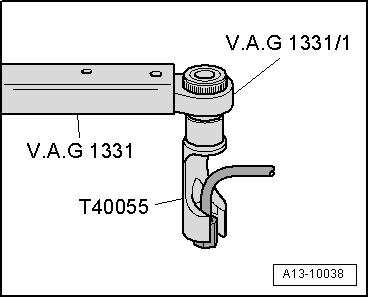

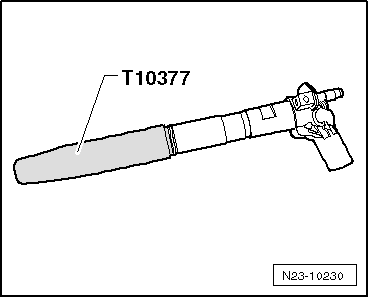

| Install the new copper gasket ring with the aid of a plastic bush. |

|

|

|

Note

Note

Note

Note