Roomster

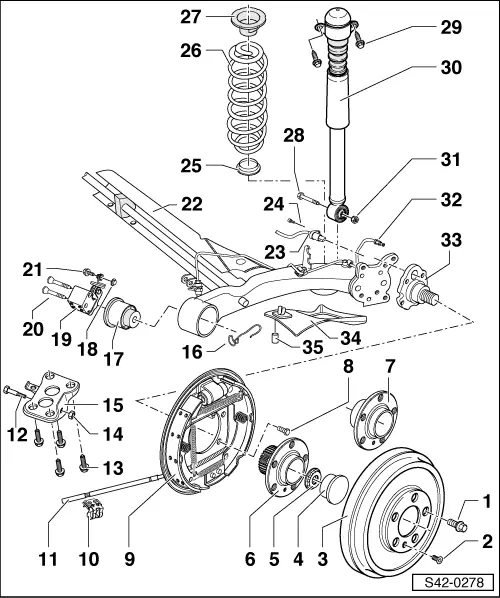

| Summary of components of rear axle with drum brake |

Note

Note| t | Welding and straightening on axle body and axle studs not allowed. |

| t | Always replace the self-locking nuts and screws. |

| t | Always replace corroded self-locking nuts and screws. |

| t | Generally tighten the brake line pipe screws to a tightening torque of 14 Nm. |

| 1 - | Wheel bolt |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | Tightening torque → Chapter |

| 2 - | Screw, 4 Nm |

| 3 - | Brake drum |

| q | Brake drum diameter, wear limit → Chapter |

| q | clean carefully, and check for wear, damage, dimensional accuracy and perfect brake surface |

| q | reset brake before removing the brake drum → Chapter |

| q | Thoroughly clean the centering hole of the drum before installing and subsequently treat it with approx. 0.5 g of anti-corrosion agent -AKR 322 000- |

Note

Note| The anti-corrosion agent -AKR 322 000- must not get into the threads of the wheel screws! |

| 4 - | Cap |

| q | replace after each removal |

| q | extracting and inserting → Chapter |

| 5 - | Self-locking twelve-point nut 70 Nm +40° |

| q | replace after each removal |

| 6 - | Wheel hub with wheel bearing |

| q | for vehicles with ABS |

| q | Sensor ring for ABS is built into the wheel hub |

| q | wheel hub and wheel bearing form one unit; it does not need servicing. |

| q | The sensor ring for ABS cannot be replaced individually |

| q | removing and installing → Chapter |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | Before installing the brake drum, thoroughly clean the centering shoulder for the brake drum and subsequently treat it with approx. 0.5 g of anti-corrosion agent -AKR 322 000- |

Note

Note| The anti-corrosion agent -AKR 322 000- must not get into the threads of the wheel screws! |

| 7 - | Wheel hub with wheel bearing |

| q | for vehicles without ABS |

| q | wheel hub and wheel bearing form one unit; it does not need servicing. |

| q | removing and installing → Chapter |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | Before installing the brake drum, thoroughly clean the centering shoulder for the brake drum and subsequently treat it with approx. 0.5 g of anti-corrosion agent -AKR 322 000- |

Note

Note| The anti-corrosion agent -AKR 322 000- must not get into the threads of the wheel screws! |

| 8 - | Screw, 50 Nm + 60° |

| q | replace after each removal |

| 9 - | Brake carrier with brake shoe |

| q | repairing → Chapter |

| 10 - | Holder for hand-brake cable |

| q | replace after each removal |

| q | Fitting position → Chapter |

| 11 - | Hand-brake cable |

| q | removing and installing → Chapter |

| 12 - | Screw, 45Nm + 90° |

| q | replace after each removal |

| q | insert from the inside of the vehicle |

| q | tighten in unladen condition (unladen weight position) - do not load vehicle → Chapter |

| 13 - | Self-locking screw, 30 Nm + 90° |

| q | replace after each removal |

| q | if thread of the weld nut is damaged, it can be repaired using Heli-Coli threaded insert; while paying attention to the notes of the manufacturer |

| q | the rework of the thread for the weld nut is permissible on maximum 2 screw points per vehicle side |

| 14 - | Self-locking nut |

| 15 - | Mount for rear axle |

| q | avoid slackening in order to remove the rear axle |

| q | check the overall track of the rear axle after installation and adjust if necessary |

| 16 - | Holder for hand-brake cable |

| 17 - | Rubber-metal bearing |

| q | removing and installing → Chapter |

| 18 - | Socket nut |

| 19 - | Brake-power regulator |

| q | only on vehicles without ABS |

| q | testing and adjusting → Chapter |

| 20 - | Screw, 21 Nm |

| 21 - | Screw, 16 Nm |

| 22 - | Welded axle |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | The locating face and the threaded holes for axle studs must be free from enamel and dirt |

| q | removing and installing → Chapter |

| 23 - | ABS wheel speed sensor |

| q | only on vehicles with ABS |

| q | Assignment → Electronic Catalogue of Original Parts |

| 24 - | Screw, 8 Nm |

| 25 - | bottom base |

| q | inspect for damage (visual inspection) |

| 26 - | Coil spring |

| q | removing and installing → Chapter |

| q | check for paint damage, if necessary eliminate paint damage |

| q | check colour coding |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | replace axle-wise |

| q | per rear axle only use helical springs of the same make |

| 27 - | top base |

| q | installing → Chapter |

| 28 - | Screw, 40 Nm + 90° |

| q | replace after each removal |

| q | insert from the inside of the vehicle |

| q | tighten in unladen condition (unladen weight position) - do not load vehicle → Chapter |

| This operation can be skipped if the shock absorber with rear suspension has already been assembled → Chapter |

| 29 - | Screw, 30 Nm + 90° |

| q | replace after each removal |

| q | if thread of the weld nut is damaged, it can be repaired using Heli-Coli threaded insert; while paying attention to the notes of the manufacturer |

| q | the rework of the thread for the weld nut is permissible on maximum 2 screw points per vehicle side |

| 30 - | Shock absorber |

| q | removing and installing → Chapter |

| q | check → Chapter |

| q | disposing of → Chapter |

| q | can be replaced separately |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | per rear axle only use shock absorbers of the same make |

| 31 - | Self-locking nut |

| q | replace after each removal |

| 32 - | Brake line |

| q | Tightening torque of the pipe screws: 14 Nm |

| 33 - | Axle stud |

| q | Straightening work is prohibited |

| q | Re-cutting the thread is not allowed! |

| q | removing and installing → Chapter |

| 34 - | Protection against stones |

| 35 - | Fixing element for protection against stones |