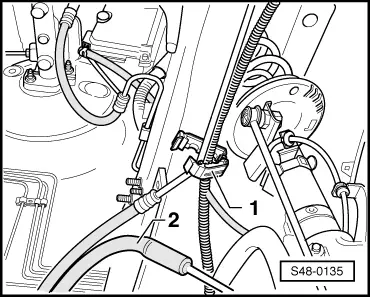

| Check the feed pressure of the engine pump aggregate TRW |

| Special tools and workshop equipment required |

| t

| Vehicle diagnosis, measurement and information system -VAS- |

| t

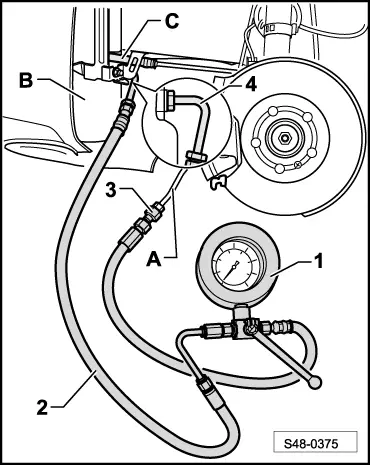

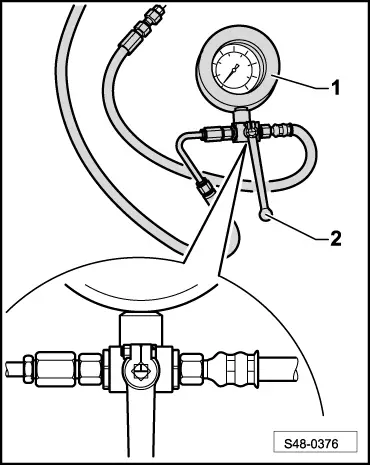

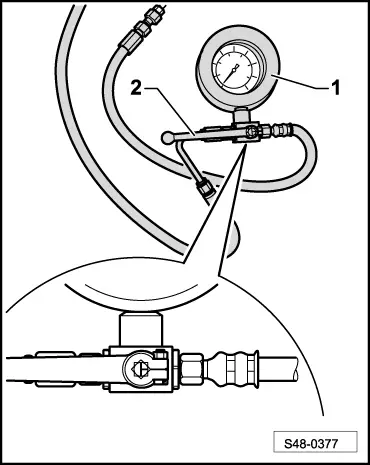

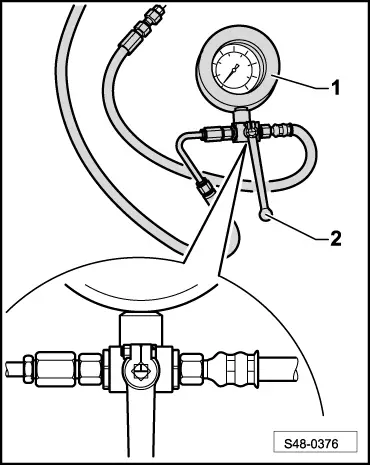

| Power-assisted steering testing device, e. g. -V.A.G 1402- |

| t

| Adapter, e.g. -V.A.G 1402/1A- |

| t

| Adapter, e.g. -V.A.G 1402/2- |

| t

| Hose from adapter set, e. g. -V.A.G 1402/6- |

| t

| Extraction bottle (commercially available) |

| t

| Jumper cable (commercially available) |

| t

| Catch pan (commercially available) |

Note | t

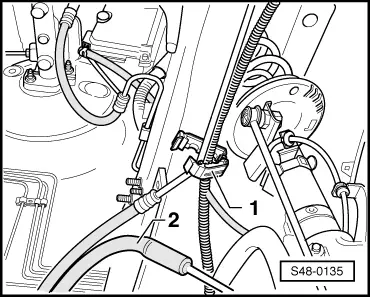

| If there is insufficient hydraulic oil in the reservoir of the engine pump aggregate always check the power-steering system for tightness → Chapter. |

| t

| If there is a leak on the power-steering gear first check the lines/line connections for tightness, if necessary retighten and wipe dry. |

| t

| Inspecting the gasket ring on the input shaft of the power-steering gear and on the gear rack seal → Chapter. If there are leaks on the gasket ring or on the gear rack seal replace the power-steering gear. |

| t

| Disposing of the power-steering gear → Chapter. |

| t

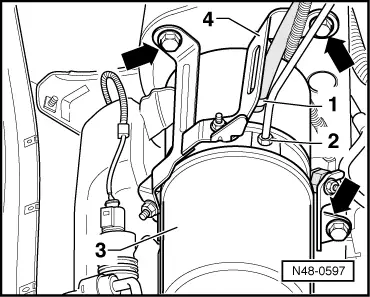

| After extraction there will be residual hydraulic oil in the engine pump aggregate as well as in the pressure line (expansion hose). |

| t

| Do not use drained hydraulic oil again. |

| t

| After the feed pressure test replace the O-ring on the pipe screw of the pressure line. |

| t

| Do not pinch off the pressure hose and the return hose with hose clamps -MP7-602 (3094)- or any other tools! Pinching off may result in damage to the pressure and return line. |

| t

| To avoid damage make sure the bending radius of at least 100 mm is respected when bending or tying up the pressure line. |

| l

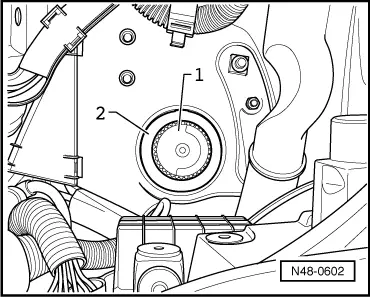

| Tightness of the system |

| l

| Pressure and return line not buckled or tied up. |

Note | t

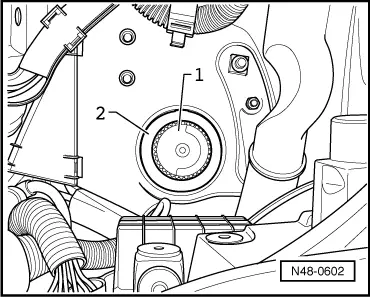

| Because of the different dimensions of the battery the screw cap of the hydraulic oil reservoir on certain vehicle versions is concealed by the battery tray and battery. If this is the case remove the air filter, the battery and the battery tray. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution