| –

| Position the digital depth gauge twice at opposite-facing points for a precise measurement. |

| In this way, an even more precise value is determined as the inaccuracy resulting from the »wobbling« on the engaging bearing is thus minimised. |

| –

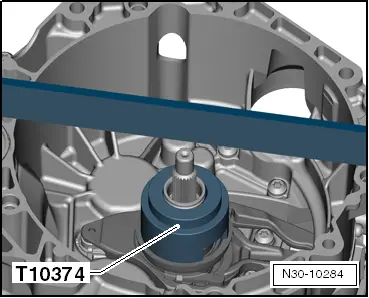

| Calculate the mean value of both measurements to the gauge block -T10374-. |

| –

| Note this value and name it „A1“. |

| As an example: „A1“ = 2.71 mm |

| The following calculation: |

| „A1“ minus „B“ plus height of the gauge block -T10374- = depth of the engaging bearing of clutch 1. |

| The height of the gauge block -T10374- is always the same. It is: 51.81 mm. |

| 2,71 mm minus 2.96 mm plus 51,81 mm = 51,56 mm. |

| You have now determined the value of how deep the engaging bearing is actually positioned in the gearbox. |

| The depth of the bearing must be 50.08 mm on each gearbox. |

| The nominal dimension „50,08 mm“ is deducted from the actual dimension. Thus, the actual air passage of clutch 1 is determined. |

| –

| Continue the calculation: |

| The determined value (in the example: 51,56 mm) minus the nominal value = the air passage of the clutch. |

| 51,56 mm minus „50,08 mm“ = air passage of clutch 1 = 1,48 mm. |

| Now the tolerances in the double clutch must be included in this calculation. This is a very simple procedure: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING