| –

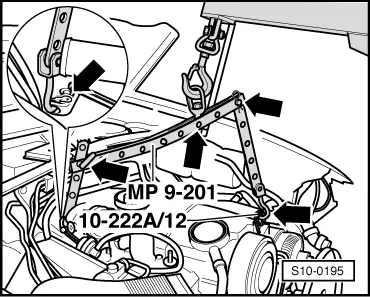

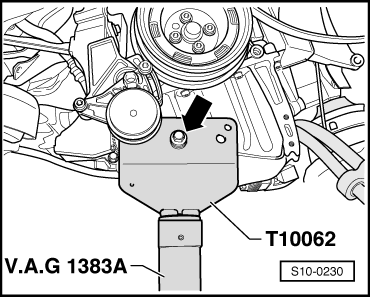

| Unscrew the torque converter from the driver plate, do this by screwing out the screws through the starter opening (the crankshaft must be further turned by 1/3rd of a turn in its direction of rotation of engine). |

Note | t

| To loosen the screws on the torque converter counterhold at the central screw of the V-ribbed belt pulley. |

| t

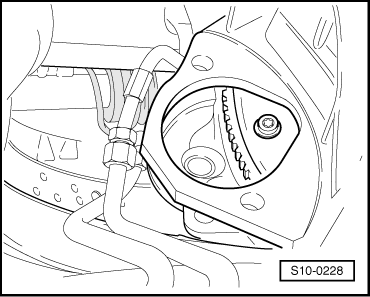

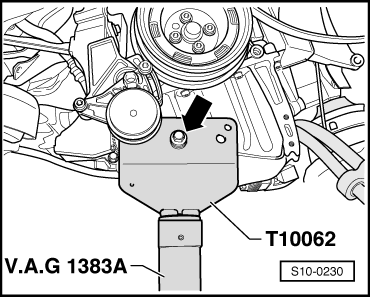

| When removing the engine, counterhold the torque converter through the starter opening in the gearbox with the help of a second mechanic. |

| t

| Secure the torque converter before removing the engine against “dropping down”. |

| Continued for all vehicles |

| –

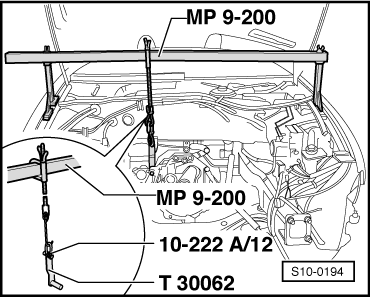

| Remove the upper engine/gearbox connecting screws. |

Note | Just loosen a connecting screw, but do not screw out immediately. |

| –

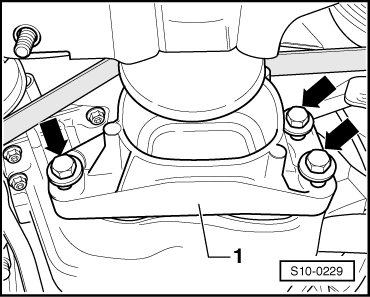

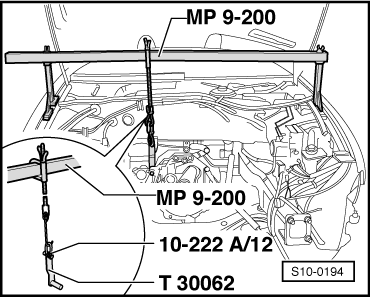

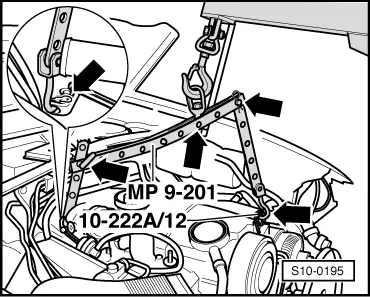

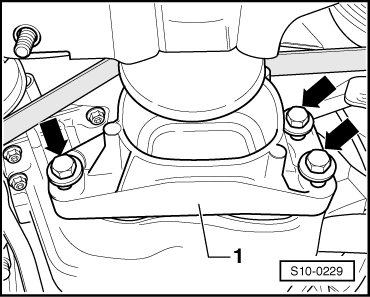

| Unscrew the fixing screws for the engine mounting on the upper right and left. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note