| –

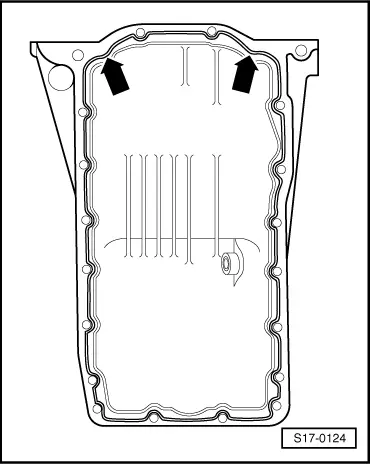

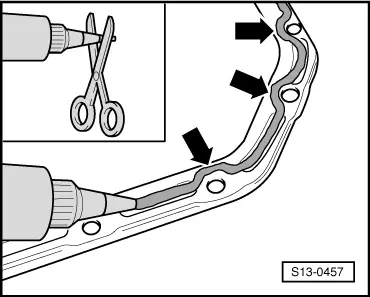

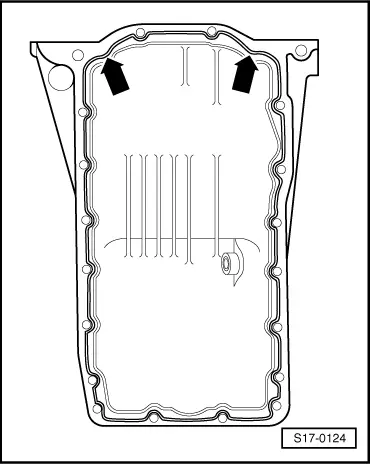

| Apply silicone sealant to the clean sealing surface of the oil pan, as shown in the illustration. |

| –

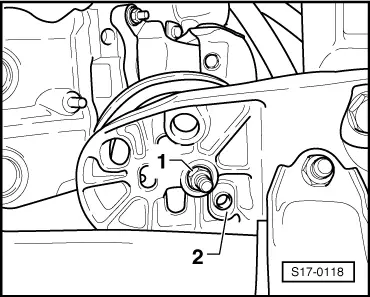

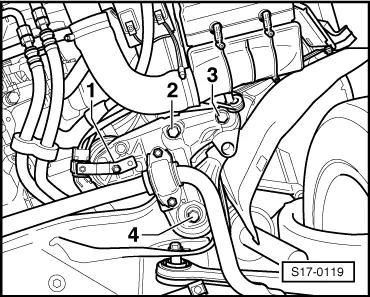

| Place the M10 bolts in the oil pan at the cylinder block before assembling on the oil pan. |

| –

| Immediately position the oil pan and slightly tighten all oil pan bolts. |

| –

| Tighten up the M7 oil pan bolts crosswise using a torque of 15 Nm. |

| –

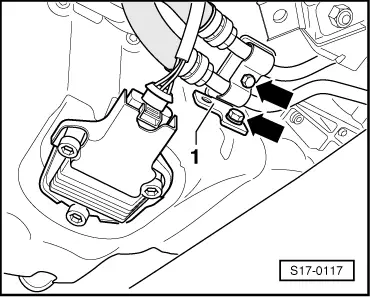

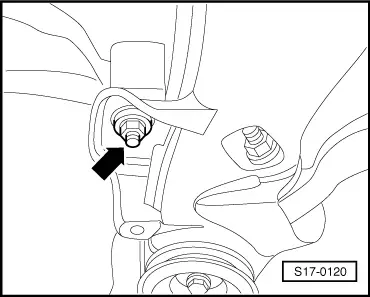

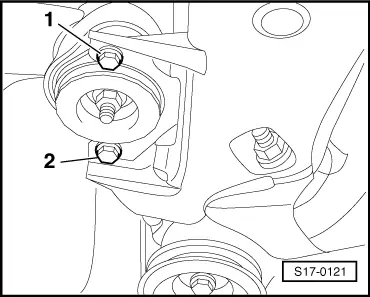

| Tighten up the M10 bolts on the oil pan/cylinderblock using a torque of 40 Nm. |

| –

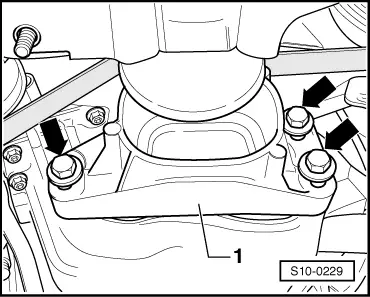

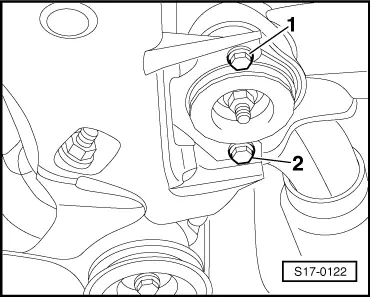

| Tighten up the bolts on the oil pan/gearbox to a torque of 45 Nm. |

Note | After installing, allow the sealant to dry for about 30 minutes. Only after this period has elapsed the engine oil can be poured in. |

| Further installation occurs in reverse order to removal. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING