Superb

| ATF supply |

Caution

Caution

|

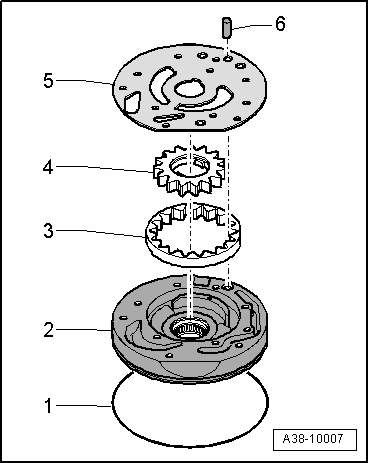

| 2 - | Mounting ring |

| q | check for deformation |

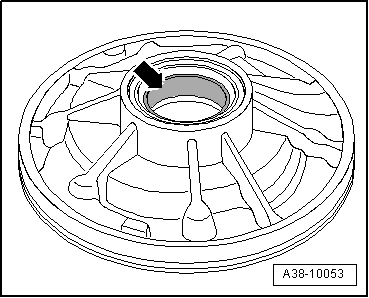

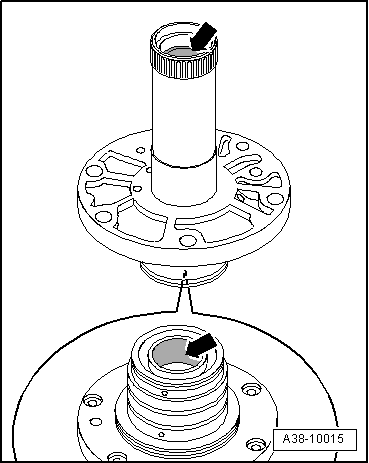

| 4 - | ATF pump housing |

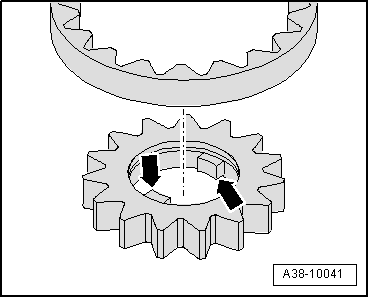

| q | Check contact surfaces for traces of scoring and friction → Fig. |

| q | check brass bush for wear → Fig. |

| 5 - | Ring gear |

| q | Check contact surfaces for traces of scoring and friction → Fig. |

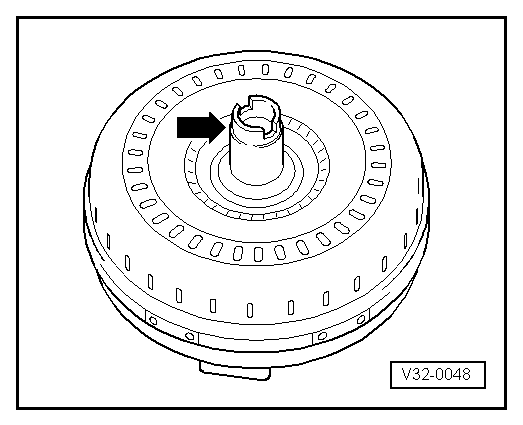

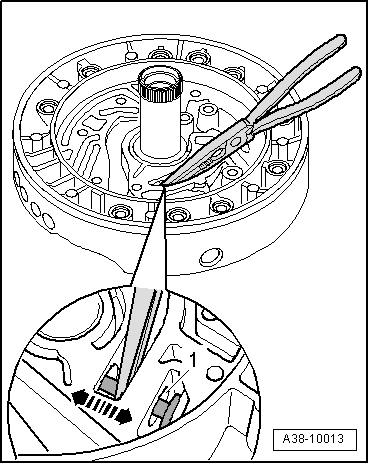

| 6 - | ATF pump gear |

| q | Check contact surfaces for traces of scoring and friction → Fig. |

| q | Check driver in ATF pump gear → Fig. |

| 8 - | Intermediate plate |

| q | Check contact surfaces for traces of scoring and friction → Fig. |

| 10 - | ATF supply |

| q | Check quantity regulating valve of ATF supply for smooth operation → Fig. |

| 13 - | Stator shaft |

| q | check brass bush for wear → Fig. |

| q | check serration for wear |

| q | must be positioned in the housing for ATF supply pos. 10, replace both parts in case of loose position |

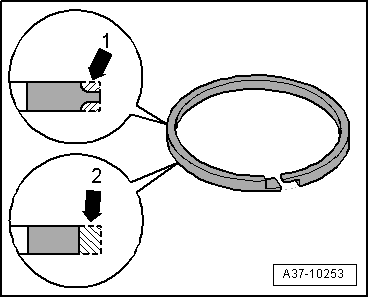

| 16 - | Rectangular ring for clutch “A” |

| q | check for wear → Fig. |

| 17 - | Axial needle bearing |

| q | Perform visual inspection for damage: Axial needle bearing and its contact surfaces must be like new, replace if necessary |

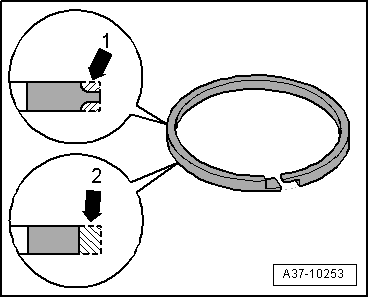

| 18 - | Rectangular rings for clutch “B” |

| q | check for wear → Fig. |

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|