Superb

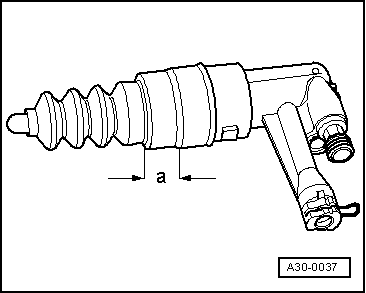

| 1 - | Slave cylinder |

| q | installing → Fig. |

| q | when installing, press in until the fixing screw Pos. 2 can be installed |

| q | Tighten the vent valve to 4 Nm. |

| q | Bleed the clutch system → Chapter |

| 2 - | 20 Nm |

| q | self-locking |

| q | always replace → Electronic Catalogue of Original Parts |

| 3 - | Support |

| q | fixed to gearbox with slave cylinder |

| 4 - | Tappet |

| q | Lubricate the tappet end with copper grease -N 052 159 00- |

| 5 - | Disc spring |

| q | smaller diameter (curved side) to guide bushing |

| 6 - | Gasket ring for drive shaft |

| q | pull out from the guide bushing with ejection lever -MP3-418- |

| q | drive up to the stop with drive bushing -T30024- |

| 7 - | Screw |

| q | self-locking |

| q | always replace → Electronic Catalogue of Original Parts |

| q | black, only for gearbox made out of aluminium |

| q | glossy, for gearbox made out of aluminium and magnesium |

| q | assign → Electronic Catalogue of Original Parts |

| q | on aluminium gearboxes |

| t | 35 Nm |

| q | on magnesium gearboxes |

| t | 25 Nm |

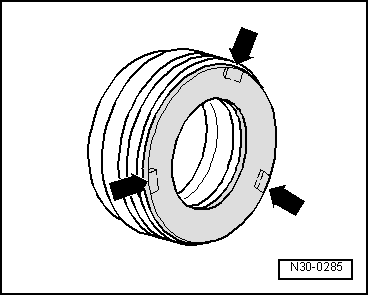

| 8 - | Clutch release bearing |

| q | stick on released plastic ring → Fig. |

| q | Do not wash the bearing, just wipe clean |

| q | replace noisy bearings → Electronic Catalogue of Original Parts |

| 9 - | Clutch release lever |

| q | before installing, thinly lubricate the contact for the slave cylinder tappet with copper greaset -N 052 159 00- |

| 10 - | Retaining spring |

| q | attach to clutch release lever |

| 11 - | Guide bushing |

| q | before removing/sliding on for protection of the gasket ring Pos. 6, pull the shrink hose over the serration of the drive shaft |

| q | Fitting position: Oil drain hole points downwards |

| q | Guide bushings made out of various materials for gearbox made out of aluminium and magnesium |

| q | assign → Electronic Catalogue of Original Parts |

| 12 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 13 - | Intermediate piece |

| 14 - | Ball pin |

| q | grease with copper grease -N 052 159 00- |

| q | Ball pin made out of various materials for gearbox made out of aluminium and magnesium |

| q | assign → Electronic Catalogue of Original Parts |

| q | on aluminium gearboxes |

| t | 25 Nm |

| q | on magnesium gearboxes |

| t | 20 Nm |

| 15 - | Gearbox |

|

|

|

|