Superb

|

| (Gearbox removed) |

Note

Note| t | “SAC” stands for Self-Adjusting-Clutch and means “self-adjusting clutch”. |

| t | Replace the clutch discs and pressure plates if the riveting is damaged or loose. |

| t | Assign the clutch disc and pressure plate via the → Electronic catalogue of original parts and in accordance with the engine identification characters. |

| 1 - | Flywheel |

| q | make sure the centering pins are tight |

| q | The locating face for the clutch lining must be free from grooves, oil and grease |

| q | Removing and Installing → Engine; Rep. Gr.13 |

| 2 - | Needle bearing |

| q | Removing and Installing → Engine; Rep. Gr.13 |

| 3 - | Screws for flywheel |

| q | Tightening torque → Engine; Rep. Gr.13 |

| 4 - | Clutch disc |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | Fitting position: Shock absorber package (coil springs) or inscription “side of gearbox” to pressure plate or to gearbox |

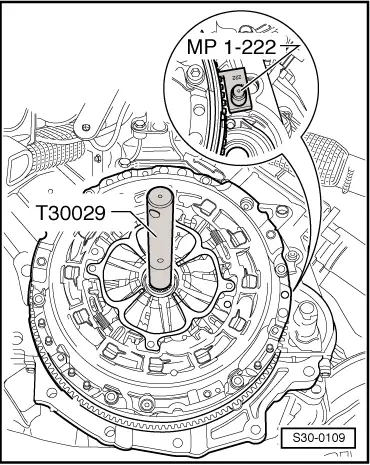

| q | center → Fig. |

| q | slightly grease the serration |

Note

Note| Clean the drive shaft serration and hub serration on used clutch discs, remove corrosion. Only apply a very thin layer of grease -G 000 100- onto the serration of the drive shaft. Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. Remove all excess grease. |

| 5 - | SAC pressure plate |

| q | removing and installing → Fig. |

| q | Reset adjustment ring → Chapter |

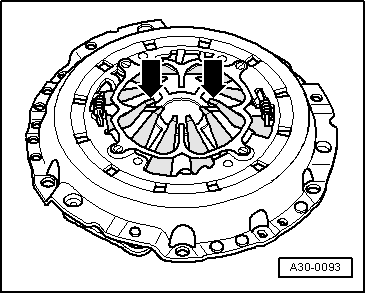

| q | Check the extremities of the membrane springs → Fig. |

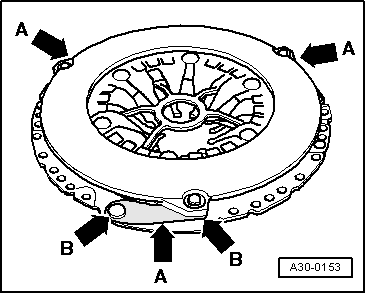

| q | Check feather and riveted joints → Fig. |

| 6 - | 22 Nm |

| q | Release or tighten gradually and crosswise |

|

|

|

|