| t

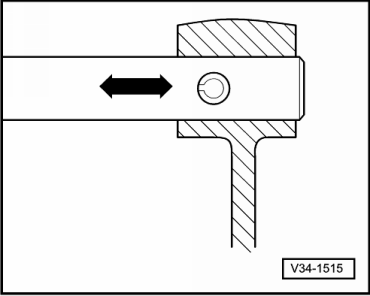

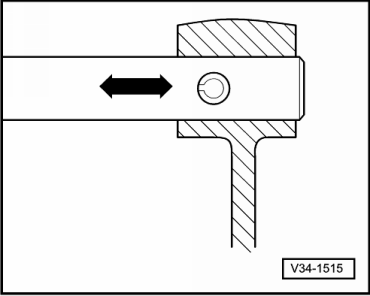

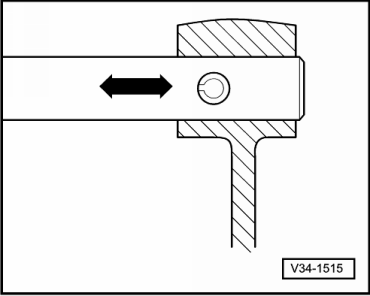

| Replace roll pins. Fitting position: slot longitudinally to power flow. |

| t

| Slacken and tighten nuts and bolts for attaching covers and housings diagonally across. |

| t

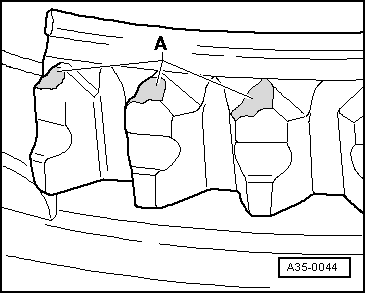

| Do not twist particularly sensitive parts - e.g. clutch pressure plates - and slacken and tighten diagonally across in stages. |

| t

| Tightening torques apply for non-oiled nuts and bolts. |

| t

| It is important to ensure at all bolted connections that the contact surfaces as well as the nuts and bolts are waxed only after being installed, should this be necessary. |

| t

| Clean all threaded holes into which self-locking bolts are inserted, with a thread tap to remove residues of the locking fluid. Otherwise there is a risk that the bolts will shear at the next disassembling. |

| t

| Position needle bearing, ball sleeves and roller sleeves with the lettered side (thicker end) towards the drift pin. |

| t

| New taper roller bearings are fitted as supplied and do not require any additional lubrication. |

| t

| Insert all bearings (except tapered-roller bearing) in the gearbox with gear oil. |

| t

| Heat the inner rings of the tapered-roller bearing to approx. 100°C for installing, press up to the stop until there is no axial play when assembling. |

| t

| Heat the inner rings for needle and roller bearing to maximum 130°C. |

| t

| Do not exchange the outer and inner rings of bearings of the same size - bearings go in pairs. |

| t

| Jointly replace tapered-roller bearings on the same shaft and use products of the same manufacturer. |

| t

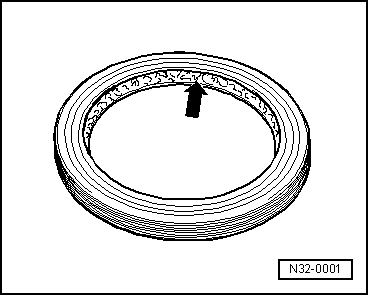

| Check the double angular ball bearing → Chapter with the secondary shaft fitted and the differential removed for wear (running noises). “When turning the secondary shaft, the bearing must not hook or run rough”. |

| t

| If the drive chain was replaced or metal swarf is found in the engine oil, then the double angular ball bearing on the secondary shaft must always be replaced. |

| t

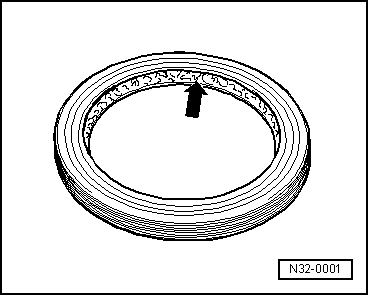

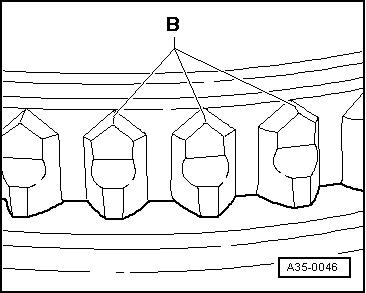

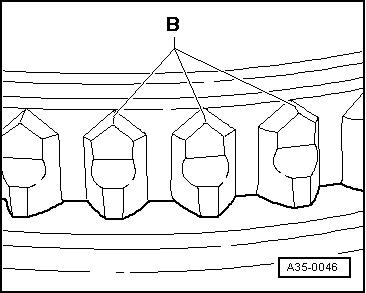

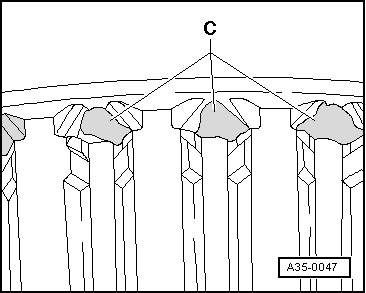

| Gauge shims at several points with a micrometer. Different tolerances allow to measure the required thickness for each washer very precisely. |

| t

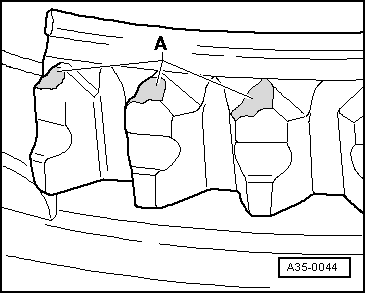

| Inspect for burrs and damage. |

| t

| Install only undamaged shims which are in perfect condition. |

| t

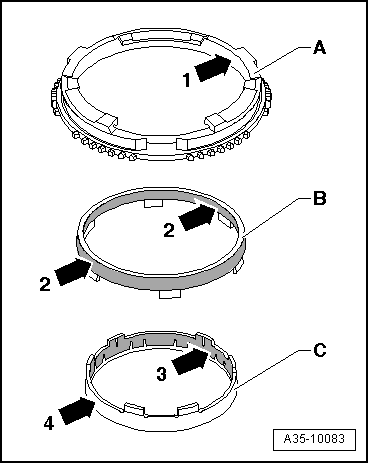

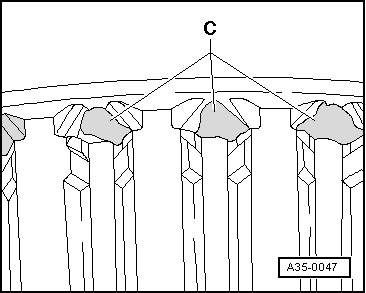

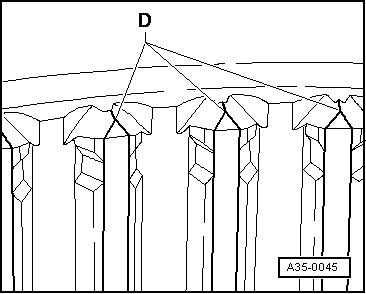

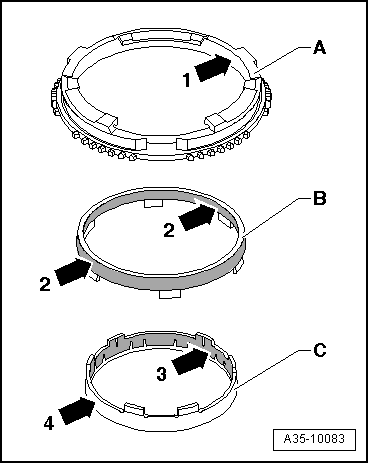

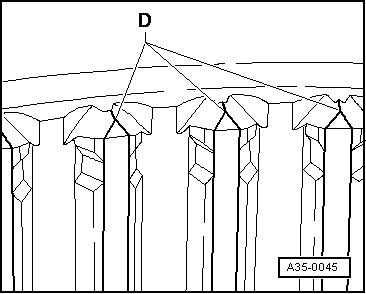

| These are not interchangeable. If re-using, allocate synchronizer rings to the same gear. |

|

|

|